|

IN BRIEF

|

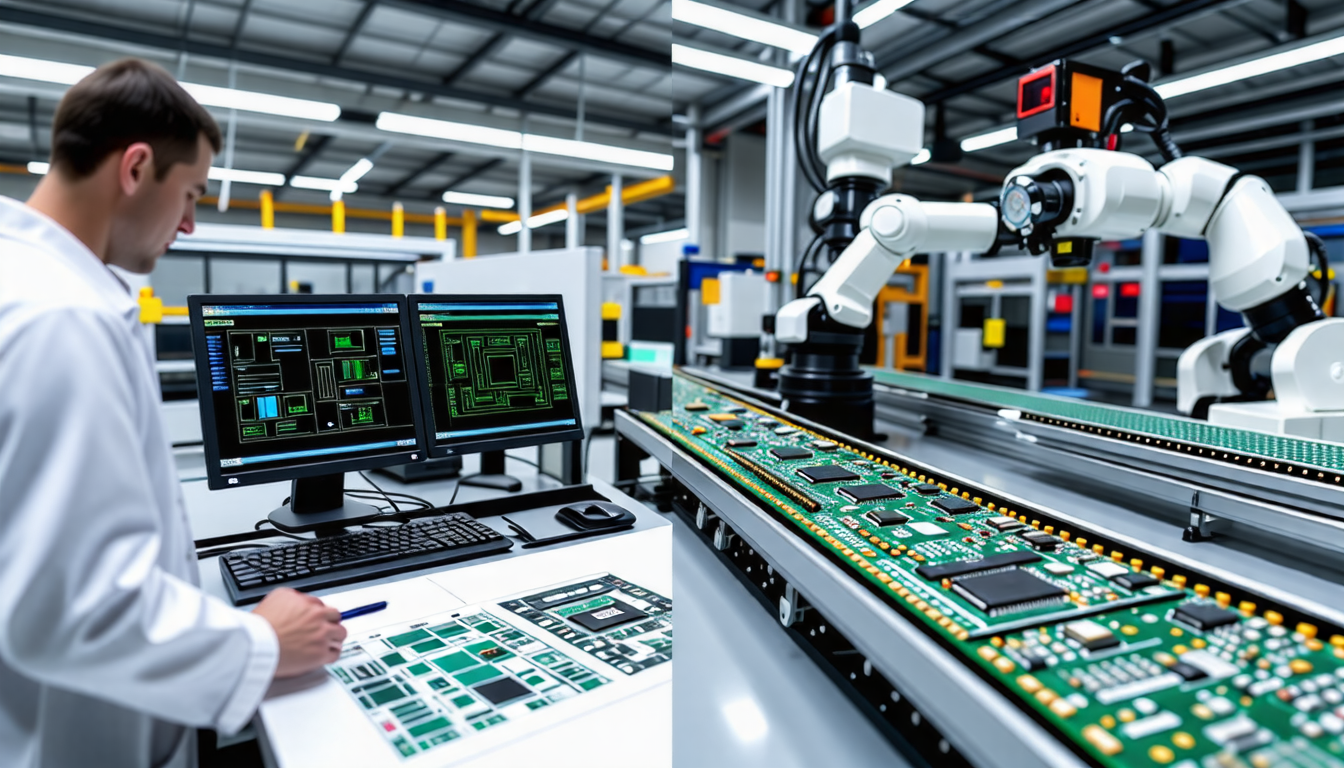

In today’s fast-paced technological landscape, the realm of smart appliances is experiencing a meteoric rise, transforming the way we live and interact with our homes. However, behind the allure of connectivity and convenience lies a labyrinth of manufacturing challenges that producers must navigate to bring these innovations to life. From outdated infrastructure that hinders implementation to the crucial issue of interoperability among devices, manufacturers face an uphill battle as they strive to merge cutting-edge technologies with consumer expectations.

As we delve into the complexities of creating smart appliances, we uncover not only the hurdles, but also the immense potential that lies within this dynamic sector, paving the way for a future where our homes are more intuitive than ever.

The demand for smart appliances has skyrocketed as consumers increasingly seek connectivity and efficiency in their homes. However, manufacturing these innovative devices presents numerous challenges that can hinder the adoption of smart technology. This section delves into the multifaceted obstacles that manufacturers encounter in this evolving landscape.

Future Directions for Smart Appliance Manufacturing

The future of smart appliance manufacturing is intertwined with various trends that shape the industry landscape. As technologies such as artificial intelligence and machine learning continue to evolve, manufacturers can tap into new growth opportunities. By leveraging these technologies, companies can enhance the functionality of their appliances, offering consumers personalized solutions that adapt to their lifestyles.

Collaborative efforts between manufacturers, software developers, and technology providers are vital. Such partnerships can pave the way for innovations that not only address existing challenges but also anticipate future needs. By remaining engaged with industry trends and consumer feedback, manufacturers can navigate the complex landscape of smart appliance production while continuing to enhance the connected experience in households.

In light of these challenges and opportunities, it is crucial for manufacturers to understand the landscape of smart appliances comprehensively. For further insights on the key stages in the manufacturing process of home appliances, visit the following link: Key Stages in the Manufacturing Process.

As they face these hurdles, manufacturers must also try to balance compliance with evolving environmental regulations. An overview of these regulations can be accessed at: Understanding Environmental Regulations.

Interoperability and Compatibility Issues

Interoperability poses a significant challenge in the realm of smart appliances. With various manufacturers developing devices that use a range of communication protocols, achieving seamless interaction between different smart appliances can be problematic. This can frustrate consumers who expect their devices to work together effortlessly. To address interoperability, manufacturers need to work collaboratively and establish universal standards that enhance compatibility among devices, ultimately improving user experience.

Data Security Concerns

The integration of the Internet of Things (IoT) technologies into smart appliances introduces various security vulnerabilities. As these devices collect and transmit data, they become prime targets for cyberattacks. Ensuring that built-in security features are robust enough to protect sensitive information poses a substantial challenge. Manufacturers must invest in advanced security measures while balancing consumer privacy with innovation. Conducting regular security assessments and implementing updates is crucial for maintaining integrity and trust.

The landscape of smart appliance manufacturing is rapidly evolving, yet it is not without its challenges. One significant hurdle is the presence of outdated infrastructure, which complicates the integration of cutting-edge technologies. As manufacturers strive to adopt the latest innovations, lingering legacy systems often hinder progress. According to recent studies, nearly 40% of manufacturers report difficulties in modernizing their facilities, resulting in inefficiencies that can stymie growth.

Additionally, the issue of interoperability emerges as a crucial barrier. As connected devices proliferate, ensuring seamless communication amongst various products becomes imperative. The inability of devices to communicate can lead to consumer frustration and undermine the potential of smart technology. Experts predict that by 2025, interoperability will be pivotal for 80% of smart appliance users, making it a top priority for manufacturers.

Security is another formidable challenge; with data breaches and cyberattacks on the rise, protecting user information is paramount. Manufacturers find themselves tasked with not only innovating but also safeguarding their users. Addressing these hurdles can unlock a realm of possibilities, driving the smart appliance market towards unprecedented growth and enhancing overall user satisfaction.

The emergence of smart appliances has transformed everyday life, providing connectivity and energy efficiency, yet they bring a range of manufacturing challenges that must be addressed. One significant hurdle is the existing legacy systems that complicate the adoption of innovative technologies. Moreover, interoperability remains a pressing concern as manufacturers strive to ensure their products work seamlessly with one another. Additionally, security issues pose risks that require robust solutions. As the landscape evolves at lightning speed, it’s imperative for manufacturers to adapt and optimize their processes, keeping in mind the future of smart manufacturing and the expectations of consumers who increasingly demand advanced functionality in their devices.

FAQ

What are the main challenges in manufacturing smart appliances?

R: The primary challenges include interoperability between devices, outdated infrastructure, ensuring security, and limitations related to hardware. Additionally, manufacturers face issues like service constraints and integration difficulties.

How do outdated systems impact smart appliance manufacturing?

R: An old system infrastructure can hinder the implementation of modern smart manufacturing technologies. It can create compatibility issues and slow down the adoption of new innovations.

Why is interoperability important for smart appliances?

R: Interoperability ensures that various connected devices can communicate effectively with each other. This is crucial for user experience and enables manufacturers to gather valuable data on usage patterns, which can inform future product development.

What role does data play in overcoming manufacturing challenges?

R: Data collected from smart appliances helps manufacturers understand customer usage and preferences. This information can be pivotal in designing better products and addressing existing challenges in manufacturing.

How can manufacturers address security concerns in smart appliances?

R: Manufacturers can enhance security by implementing robust security protocols, conducting regular security audits, and ensuring that all components are designed with security features in mind. This approach can help reassure consumers and improve overall product integrity.