|

IN BRIEF

|

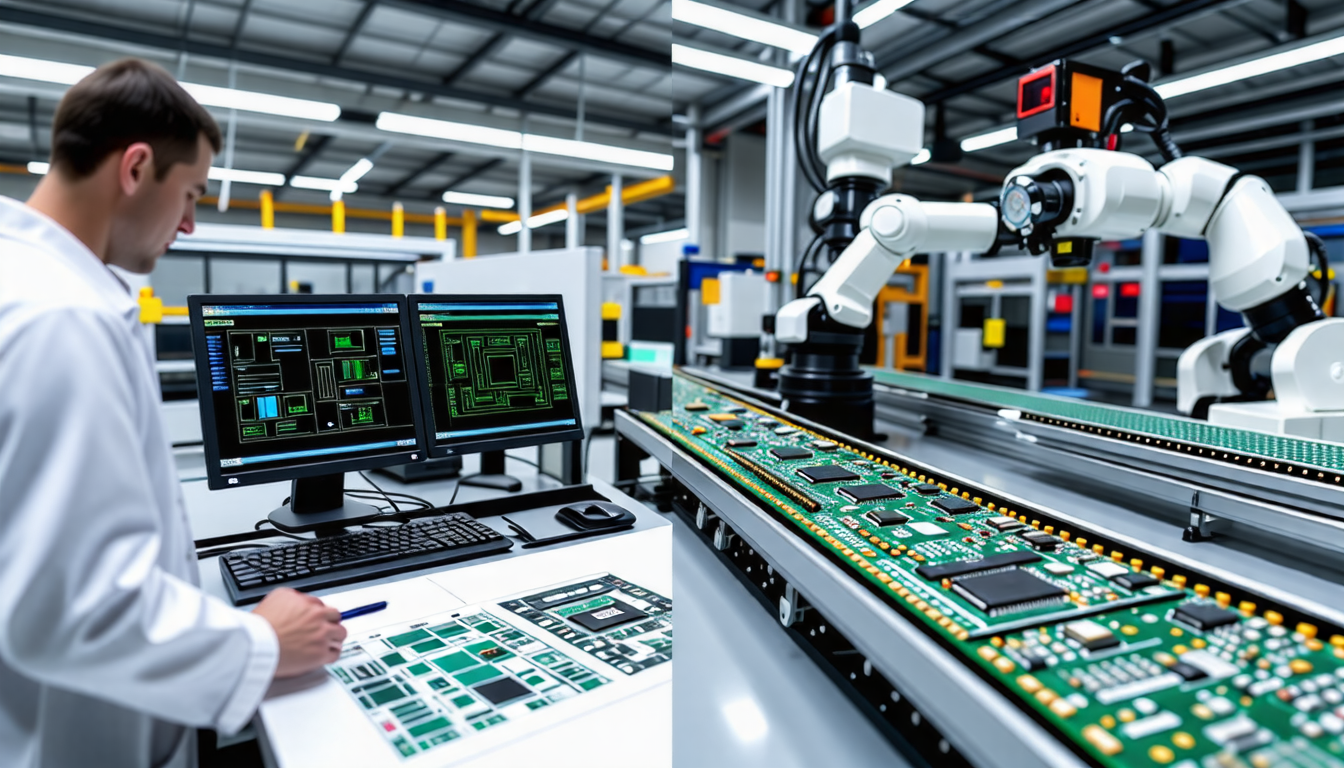

In an era where innovation is at the forefront, automation has revolutionized the landscape of appliance manufacturing. This technological leap isn’t just about machines taking over human roles; it’s a powerful enhancement of production efficiency and precision. With the advent of robotics and intelligent systems, manufacturers can streamline processes, reduce costs, and dramatically increase productivity. Picture a factory floor where complex appliances are assembled with pinpoint accuracy, minimizing errors and maximizing compliance. The incorporation of artificial intelligence not only supports these advancements but also cultivates an environment where workers can focus on more sophisticated tasks. As automation redefines the traditional workflows, it boldly shapes the future of the appliance industry, ensuring that innovation remains at its core.

In the realm of appliance manufacturing, automation has emerged as a transformative force. The integration of advanced technologies is revolutionizing the way products are designed, created, and delivered to consumers. From smart robotics to sophisticated AI systems, automation is enhancing efficiency and productivity, shaping the entire landscape of the manufacturing process.

Current Trends in the Appliance Manufacturing Industry

The appliance manufacturing landscape is continuously evolving. With the rise of IoT (Internet of Things) technology, appliances are becoming smarter and more connected. This trend necessitates the adaptation of manufacturing processes to accommodate features such as remote control capabilities and energy efficiency. Automation streamlines the production of these advanced appliances, enabling manufacturers to stay ahead in this competitive field.

The Importance of Key Stages in Manufacturing

Understanding the key stages in the manufacturing process of home appliances is vital for ensuring that automation is implemented effectively. Various phases include design, parts procurement, assembly, testing, and distribution. Automation can enhance every stage, creating a seamless flow that reduces time to market. For an in-depth examination of these stages, check out this article. By making the most of automation across different stages, manufacturers can cultivate a robust and efficient workflow.

The Future of Automation in Appliance Manufacturing

Automation in appliance manufacturing is not merely a trend; it is the future. As technology continues to advance, the integration of AI, robotics, and data analytics will further redefine best practices within the industry. Manufacturers who embrace these changes will be better equipped to meet consumer expectations, respond to market shifts, and drive innovation. Staying ahead in this rapidly changing landscape will require a commitment to continuous improvement and an openness to redefining operational strategies.

The Role of Robotics in Reducing Labor Strain

Another vital aspect of industrial automation is its ability to alleviate the physical strain associated with manual labor. As robotics takes over cumbersome or hazardous tasks within the manufacturing environment, workers are given the opportunity to engage in more complex and intellectually stimulating duties. This shift not only enhances the work environment but also leads to greater job satisfaction among employees. Furthermore, automation allows for a safer workspace, reducing the number of workplace injuries significantly.

Adapting to New Industry Requirements

The appliance manufacturing sector faces constant challenges, from evolving consumer demands to regulatory changes. Automation enables manufacturers to adapt swiftly to these shifts. For instance, with smart appliances becoming increasingly popular, companies leveraging automation can integrate customization options at a scale that manual processes simply cannot match. By utilizing data analytics and customer feedback, production lines can be adjusted in real-time to meet specific consumer requirements, fostering innovation and competitiveness.

The impact of automation on appliance manufacturing is becoming increasingly profound. Recent studies indicate that automation technologies can elevate production rates by up to 30%, significantly enhancing productivity. The adoption of robotics in the manufacturing process alleviates the physical strain on workers, creating a more comfortable and efficient work environment. This shift not only boosts worker safety but also allows for a redefinition of skills required in the workforce.

Moreover, with automation, companies are seeing improved compliance capabilities, as machines ensure the assembly of all appliance parts meets stringent regulations. For example, automated assembly lines can now reduce manufacturing costs by nearly 25%, enabling companies to provide competitively priced products in a market that demands affordability.

However, there is an ongoing debate regarding the implications of automation on skilled labor. On one hand, automation can diminish workers’ ability to execute manual tasks, raising concerns about job displacement. Conversely, it paves the way for new opportunities in advanced roles that require technical expertise in managing automated systems.

Thus, while automation in appliance manufacturing presents clear benefits in efficiency and cost-effectiveness, it also necessitates a strategic approach to workforce development and skills training.

The integration of automation in the appliance manufacturing landscape is not merely a trend; it’s a profound transformation reshaping the industry. By employing advanced robotics and intelligent systems, manufacturers are experiencing a surge in production efficiency and accuracy. This shift enhances compliance capabilities, as automated systems can meticulously assemble parts, ensuring quality and consistency. Moreover, the alleviation of physical strain on workers promotes a more comfortable and safer working environment. As companies leverage AI and automation to maintain their competitive edge, the traditional understanding of manufacturing roles is evolving. Although the journey comes with challenges, the benefits of this revolution are undeniable, paving the way for a future where innovation and productivity thrive hand in hand.

FAQ

What is the impact of automation on appliance manufacturing?

R: Automation significantly enhances the efficiency and consistency of appliance manufacturing processes. By integrating advanced technologies, manufacturers can streamline operations, reduce production time, and improve the overall quality of appliances.

How does automation affect production costs?

R: By implementing automation, production costs tend to decrease. Automated systems can perform tasks faster and with fewer errors compared to manual labor, which ultimately allows companies to offer their products at more competitive prices.

Are there any downsides to automation in the manufacturing process?

R: While automation increases productivity, it can also lead to a decline in certain manual manufacturing skills among workers. There may be a need for retraining to ensure that employees can adapt to automated processes, which requires a shift in skill sets.

What role do robotics play in appliance manufacturing?

R: Robotics play a crucial role by minimizing the physical strain on workers, thereby creating a safer and more comfortable work environment. They also enhance precision in assembly tasks, reducing the likelihood of defects.

How is AI changing the landscape of appliance manufacturing?

R: AI is transforming appliance manufacturing by enabling smarter automation solutions. By analyzing data and optimizing processes in real-time, AI helps manufacturers improve productivity, forecast demand, and maintain high quality standards.