|

IN BRIEF

|

In a world dominated by technology, understanding the necessary standards for electronic product safety is not just a requirement—it’s an imperative. As we continuously innovate, the mandate to protect users from potential hazards grows ever more critical. This landscape is defined not only by the complex web of regulations but also by the evolving expectations of consumers. Each device that reaches the market must traverse a series of rigorous certifications and tests, ensuring adherence to safety protocols that safeguard lives and uphold quality. This exploration into the realm of electronic safety standards reveals the vital elements that shield users from risks while fostering trust in our technological advancements. Join us as we unravel the essential metrics and guidelines that govern the dynamic world of electronic product safety.

The landscape of electronic product safety is vast and intricate, characterized by multiple regulations and standards designed to protect consumers from potential risks associated with electronic devices. Each device, be it a smartphone, laptop, or household appliance, must adhere to specific guidelines to ensure consumer safety and product reliability.

Smart Technology Regulations

As the Internet of Things (IoT) continues to expand, new challenges arise regarding safety standards for smart technologies. Manufacturers must adapt to the unique risks that come with interconnected devices and consider how data security, user privacy, and electrical safety will be governed under existing regulations.

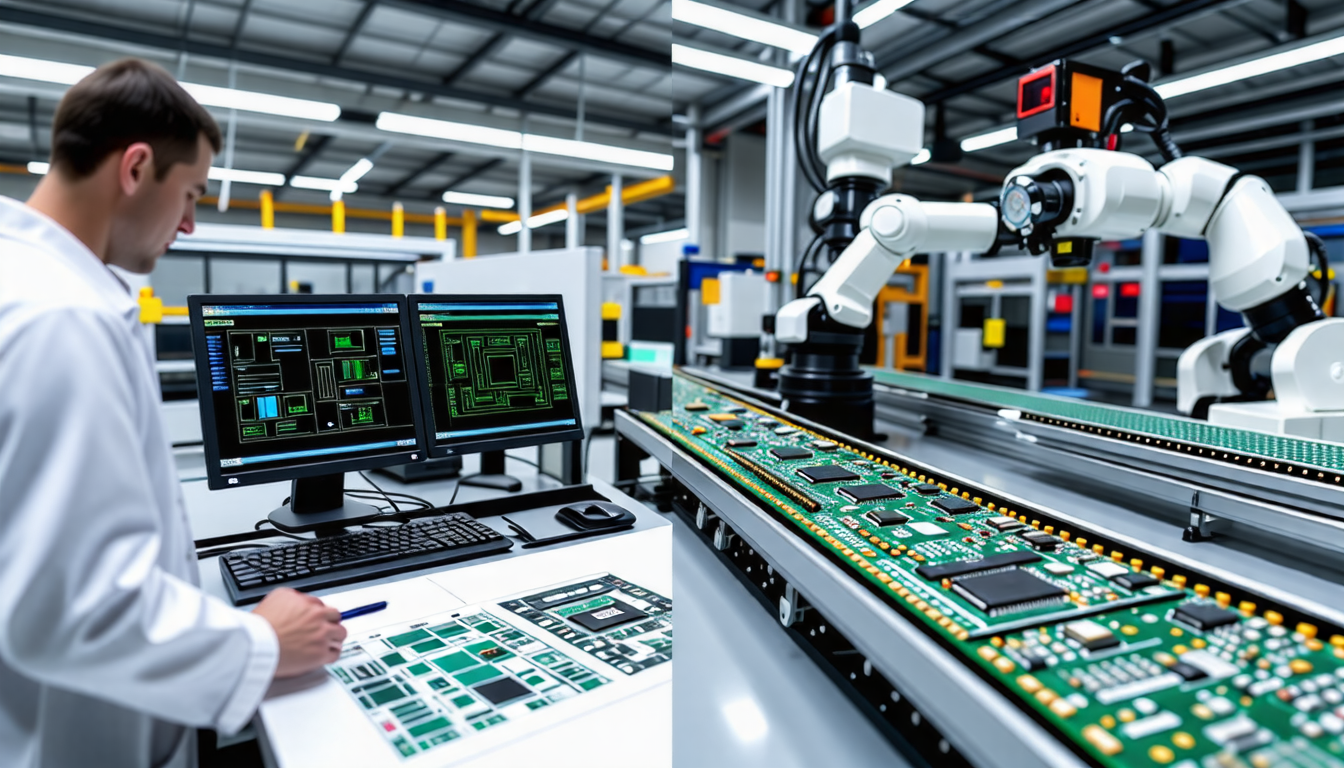

Resources like current trends in electronics manufacturing can help grasp how these shifts impact regulations and compliance for electronic products.

Understanding and adhering to electronic product safety standards is vital for protecting consumers, manufacturers, and the environment. By keeping abreast of regulations, organizations can confidently navigate compliance challenges and deliver safe, reliable products to the marketplace. From the initial design to testing and certification, each step contributes to a robust regulatory framework that ultimately promotes consumer safety and satisfaction.

Key Regulatory Bodies

Several organizations are responsible for establishing and enforcing electronic product safety standards. Among them, the Federal Communications Commission (FCC) plays a prominent role in the United States, particularly through its Title 47 CFR Part 15 regulations, which govern electronic devices to prevent interference with radio communications.

Additionally, Underwriters Laboratories (UL) and Intertek (ETL) are recognized for their product safety testing and certification, ensuring that electronic devices meet strict safety requirements. Such certifications provide consumers with confidence in the safety and functionality of the products they purchase.

In today’s electronic landscape, understanding the necessary standards for electronic product safety is pivotal for manufacturers aiming for market compliance and consumer trust. For instance, according to recent statistics, nearly 80% of electronic recalls are due to safety-related issues, emphasizing the critical nature of adherence to safety regulations.

Compliance with standards such as FCC Part 15 is crucial for devices to be eligible for the U.S. market. This regulation ensures that electronic devices minimize electromagnetic interference, which can be harmful not only to the device itself but also to others in the vicinity. Moreover, certifications like UL and ETL signify that products have met the rigorous safety standards, further instilling confidence in consumers.

It’s also important to understand the global dimension of electronic standards. For example, the IEC 60950 standard applies internationally, ensuring that electronic equipment is safe for users worldwide. In addition, compliance with directives such as RoHS highlights the industry’s commitment to reducing hazardous substances, catering to the growing market demand for sustainable electronics.

In conclusion, as the electronics market evolves, staying informed about these critical safety standards will be essential for successful manufacturing and consumer satisfaction.

Understanding the necessary standards for electronic product safety is crucial in today’s fast-paced technological landscape. Compliance with regulations such as FCC Part 15 and ISO standards not only ensures the safety of consumers but also fosters trust in the marketplace. Each manufacturer must navigate a complex web of rules concerning labeling, testing, and certification procedures to meet market demands and legal obligations. By proactively engaging in rigorous pre-testing and staying informed about changing regulatory frameworks, businesses can mitigate risks associated with product recalls and potential legal issues. Ultimately, adherence to safety standards is not just a requirement but a commitment to quality and consumer protection.

FAQ

What are the main safety standards for electronic products?

R: The primary safety standards include IEC 60950 for information technology equipment, UL standards for various consumer products, and RoHS compliance to restrict hazardous substances.

Why is compliance with electronic product safety standards important?

R: Compliance ensures that electronic products are safe for consumers, minimizing risks of accidents or hazards, and it also helps manufacturers meet regulatory requirements for market access.

How can manufacturers ensure their products meet safety standards?

R: Manufacturers can engage in thorough pre-testing, work with accredited testing labs, and stay updated on regulatory changes to ensure ongoing compliance with safety standards.

What is the role of the FCC in regulating electronic products?

R: The Federal Communications Commission (FCC) oversees compliance of electronic devices with regulations like 47 CFR Part 15, ensuring devices do not cause harmful interference and meet safety standards before entering the market.

What are common testing procedures for electronic devices?

R: Common testing procedures include electromagnetic compatibility tests, thermal tests, and component safety evaluations, which assess whether the product meets necessary compliance criteria.