|

IN BRIEF

|

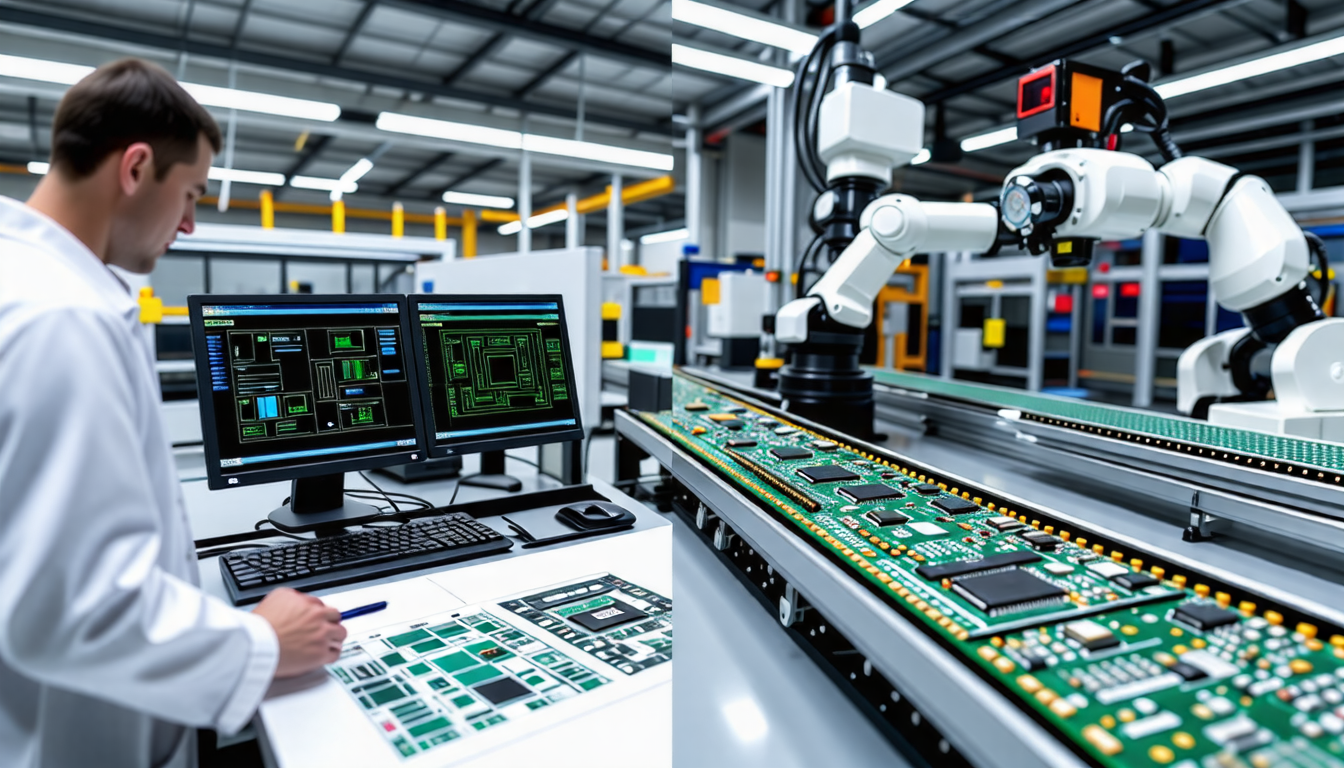

Entering the world of PCB soldering can be both exhilarating and challenging. With intricate connections and tiny components awaiting your skilled touch, mastering the art of soldering on printed circuit boards is essential for anyone venturing into electronics. A well-soldered PCB can often dictate the success of your entire project, ensuring reliability and performance. The keys to achieving impeccable solder joints lie in understanding cleaning techniques, choosing the appropriate tools, and applying flux correctly. This journey involves honing techniques that blend precision with creativity, turning each connection into a masterpiece. Whether you’re a novice or a seasoned engineer, embracing these best practices can elevate your projects to new heights, leading to flawless connections and robust devices.

Soldering is a fundamental skill for anyone involved with printed circuit boards (PCBs). Mastering the art of soldering not only improves the reliability of electronic devices but also contributes to the overall efficiency of the assembly process. By following best practices, you can ensure that your connections are solid and long-lasting. Below are essential tips to keep your soldering technique sharp and effective.

Continuous Learning and Improvement

The world of electronics is continually evolving. Commit to ongoing learning and improvement in your skills, whether by reading articles, attending workshops, or engaging in online forums. The journey of mastering soldering is an enriching one, and leveraging resources will empower you to stay ahead.

Soldering is an art that requires patience and precision. By following these best practices and continuously honing your skills, you can achieve impeccable results and craftsmanship in your PCB projects. Dive into new technologies, embrace innovations, and remain curious to expand your horizons.

Cleanliness Matters

One of the first steps in preparing your PCB for soldering is cleaning. The surfaces you’ll be soldering should be free from any oxidation or contaminants. You can use industrial cleaning wipes or acetone to thoroughly cleanse the PCB pads and component leads. This step enhances solder flow and adhesion, ultimately resulting in improved joint strength.

Effective soldering on printed circuit boards (PCBs) is crucial for ensuring the functionality and longevity of electronic devices. One fundamental practice is to start with a clean surface. Contaminants such as dust or oxidation can significantly hinder the soldering process, potentially leading to circuit failures. According to industry standards, maintaining a cleanliness threshold of ≥1MΩ on PCB surfaces is recommended to optimize solder adhesion.

Additionally, choosing the right tools is essential. A quality soldering iron with appropriate tip shape and size can enhance the soldering experience and results. Employing flux is another critical point—melting a small amount onto the PCB pads will improve solder flow and enhance bonding. Research from VSE indicated that using a suitable solder alloy can increase connection reliability by approximately 30%.

Lastly, practice on simpler components, such as resistors or capacitors, can build confidence. For more detailed guidance, resources like this step-by-step guide can offer insights into the soldering journey.

For testing procedures, refer to this overview to ensure your soldering meets quality benchmarks.

When it comes to soldering on PCBs, adopting the right practices can make all the difference in your electronic projects. Begin with a clean surface, ensuring that it is free from any dust or oxidation to promote optimal adhesion. Choosing a high-quality soldering iron and the appropriate tip size is crucial for precision. Don’t forget to apply flux to enhance solder flow and overall connections. Warm up both the PCB pad and the component lead before introducing solder for a seamless joint. Finally, practice on beginner-friendly projects to hone your skills. By following these best practices, you can master the art of PCB soldering and bring your electronic designs to life with confidence.

FAQ

What is the most important step before starting to solder on PCBs?

R: The most crucial step is to ensure that the surface is clean. You should clean the PCB and components using industrial cleaning wipes or acetone to avoid oxidation and other contaminants.

How do I choose the right soldering iron?

R: It’s essential to select a high-quality soldering iron that suits your task. Ensure the iron has the correct tip shape and size for the job you’re tackling.

What role does flux play in the soldering process?

R: Flux is vital as it enhances solder flow and adhesion. Applying a small amount of flux to the PCB pads and component leads helps create a better bond during soldering.

How should I approach soldering components on a PCB?

R: Start by soldering IC sockets first without the chips, followed by resistors, and then capacitors. This step-by-step approach ensures that you maintain a clean and organized working environment.

What is the best technique for applying solder?

R: Touch the soldering iron tip to both the PCB pad and the lead simultaneously. Allow them to heat up briefly before introducing the solder to ensure proper melting and flow.