|

IN BRIEF

|

In a world where innovation is the driving force behind progress, the realm of appliance manufacturing is experiencing a stunning transformation. As we stand at the crossroads of technology and functionality, the latest advancements are not merely improvements but revolutionary leaps that re-define our daily interactions with household devices. From the rise of smart connectivity and the seamless integration of AI into everyday appliances to groundbreaking automated manufacturing techniques, every element contributes to an eco-friendly mindset and enhanced user experience. Imagine a kitchen where your oven learns your cooking preferences, or a laundry machine that reduces energy consumption while optimizing cleaning cycles! Engage with the future as we explore the fascinating trend of sustainable innovations, making our homes smarter and more efficient than ever before.

The realm of appliance manufacturing has witnessed remarkable transformations in recent years, propelled by technological innovations. As consumer demands evolve alongside sustainability goals, manufacturers are increasingly turning to advancements that not only streamline production but also enhance product performance. This evolution is characterized by the integration of smart technologies, automation, and sustainable practices, shaping the future of household appliances.

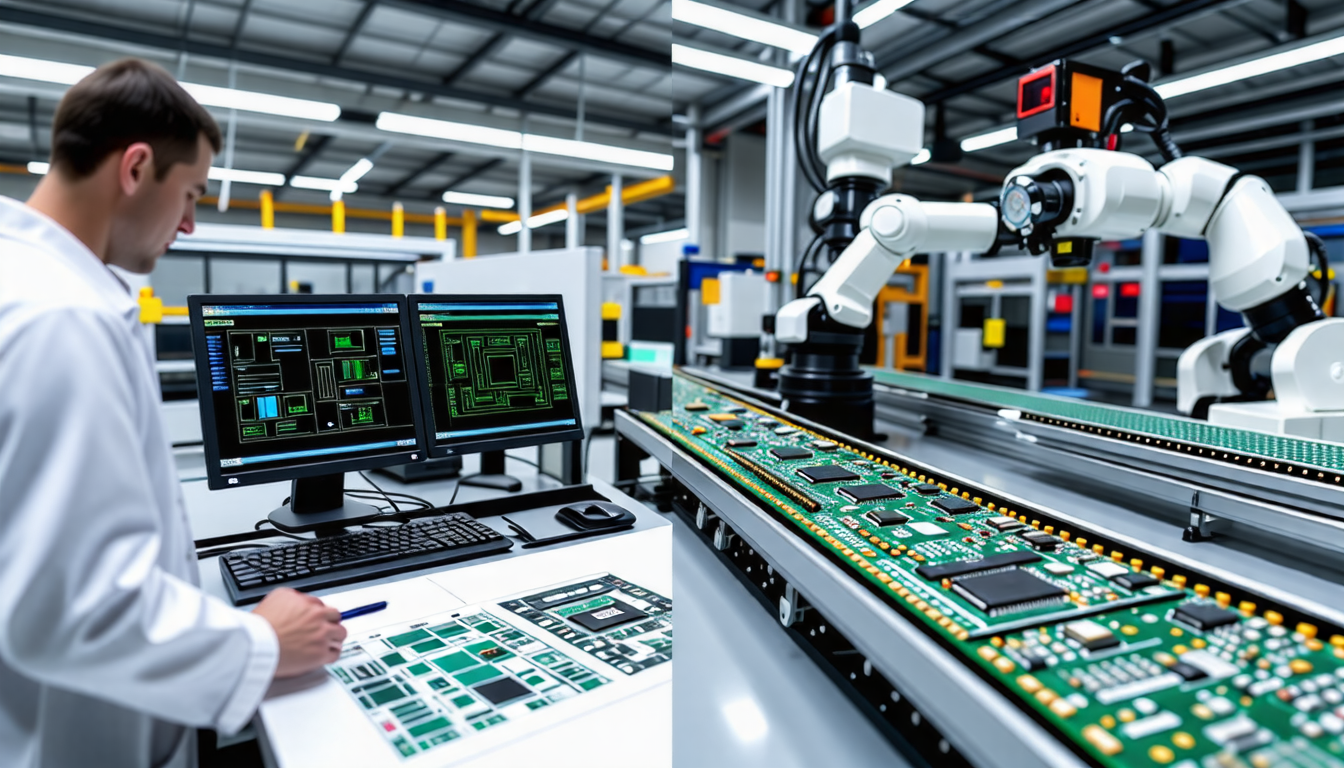

The Impact of Automation on Production

The integration of automation in appliance manufacturing brings significant shifts in how production is approached. Robotic solutions designed for heavy lifting and repetitive tasks enable manufacturers to increase their production rates without sacrificing quality. As automation technology continues to advance, the potential for greater efficiency and reduced labor costs becomes evident.

Every aspect of appliance production can benefit from automation, from assembly lines to quality assurance processes. This transformation not only enhances productivity but also allows for better management of supply chains and inventory. Manufacturers aiming to learn more about the impact of automation can refer to this resource.

As appliance manufacturing technology evolves, key advancements such as smart connectivity, AI integration, automation, and sustainability practices pave the way for an innovative future. Prioritizing these elements allows for the creation of appliances that are not only functional but also environmentally conscious, ultimately meeting the demands of a new generation of consumers.

Advancements in AI and Machine Learning

The incorporation of artificial intelligence (AI) and machine learning into appliances represents a significant step forward in manufacturing technology. These intelligent systems allow appliances to learn from user behavior and preferences over time, improving their efficiency and performance. For example, AI-enabled ovens can adjust cooking times and temperatures based on the type of food being prepared, ensuring optimal results.

Furthermore, AI is transforming the manufacturing process itself. By analyzing data collected from various stages of production, manufacturers can identify inefficiencies, predict equipment failures, and optimize workflows. Such insights enhance overall productivity while maintaining high standards of quality control.

Enhanced Manufacturing Processes

Automated assembly lines, powered by robotics, are reshaping the landscape of appliance manufacturing. Automation streamlines production processes, minimizes human error, and significantly reduces cycle times. The use of robotics for repetitive tasks in assembly not only increases production capacity but also allows skilled workers to focus on more complex tasks that require human intervention.

By implementing automation solutions, manufacturers can achieve consistent product quality and faster turnaround times. Such advancements are crucial for meeting the ever-growing demand for energy-efficient and smart appliances.

The landscape of appliance manufacturing technologies is rapidly evolving, marked by significant advancements that emphasize automation, connectivity, and sustainability. In recent years, companies have increasingly adopted automation solutions, blending mechanical systems with sophisticated controls that enhance efficiency. According to industry reports, the implementation of robotic technology can reduce production costs by up to 20% while maintaining quality standards, thus transforming assembly lines across the board.

Furthermore, the integration of Internet of Things (IoT) capabilities into appliances is revolutionizing consumer interactions. For instance, IoT-enabled devices allow real-time monitoring and remote management, making them more user-friendly and energy-efficient. A recent study indicates that homes equipped with smart appliances can achieve energy savings of approximately 30%, resonating with the growing consumer demand for sustainable solutions.

Moreover, the role of artificial intelligence (AI) within these technologies can’t be overlooked. AI-driven appliances are capable of learning user preferences, thereby optimizing energy use and improving functionality. As manufacturers aim for smarter and more environmentally friendly products, understanding the key considerations for sustainable manufacturing becomes essential for long-term success.

As we navigate through the ever-evolving landscape of appliance manufacturing technologies, it is clear that innovation is at the forefront. The integration of smart connectivity and the Internet of Things (IoT) is transforming how we interact with our household devices, making them more intuitive and responsive. Additionally, the rise of automation and robotics streamlines production processes, enhancing both efficiency and quality. Environmental considerations are also shaping the future, with manufacturers increasingly adopting sustainable practices that reduce energy consumption and waste. As user expectations continue to rise, the future of appliance manufacturing will undoubtedly focus on merging convenience with advanced functionalities, marking a significant shift in the industry.

FAQ

R: Recent advancements focus on automation and robotics, allowing for more efficient assembly lines. Innovations like smart technology and IoT integration enhance human-machine collaboration, improving productivity and quality.

How is sustainability being integrated into appliance manufacturing?

R: Sustainability efforts include the adoption of eco-friendly materials and processes that reduce energy consumption and waste. Companies are prioritizing energy-efficient products to meet consumer demand for greener choices.

What role does AI play in modern appliance manufacturing?

R: AI is revolutionizing the industry by enabling predictive maintenance, enhancing quality control, and streamlining inventory management. These capabilities allow manufacturers to respond quickly to market changes and improve overall efficiency.

How is IoT influencing the appliances we use today?

R: IoT empowers appliances to communicate with each other, providing real-time data that enhances user experience. This connectivity allows for remote control and monitoring of devices, thus improving convenience and functionality.

What future trends should we expect in appliance manufacturing?

R: Future trends include even greater levels of automation, advancements in smart technology, and a shift towards more sustainable practices. Expect to see appliances that are not only smarter but also designed with a focus on environmental impact and efficiency.