|

IN BRIEF

|

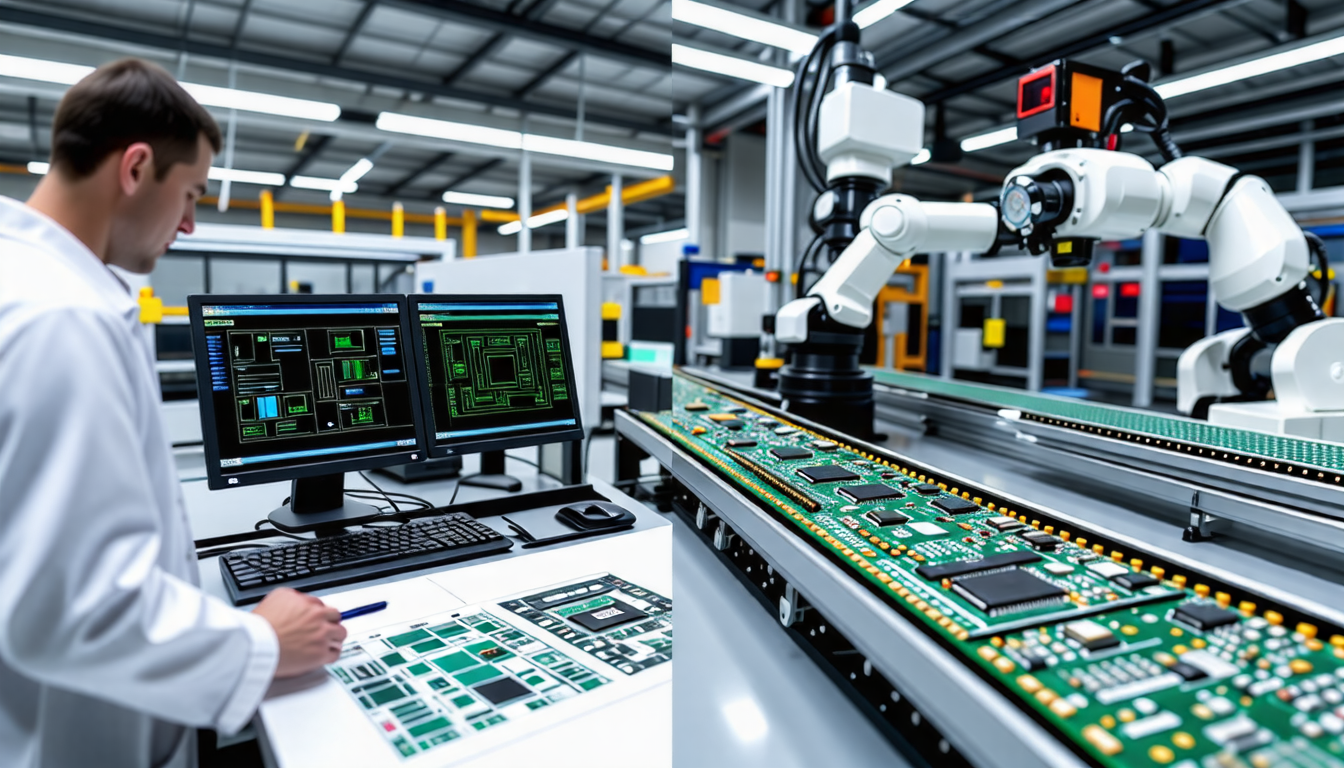

In the intricate dance of electronics, selecting the right PCB substrate can make all the difference between a robust design and a dismal failure. As we delve into the vital aspects of substrate selection, understanding both rigid and flexible materials is crucial. The choice goes beyond mere preference; it’s about harmonizing performance, cost-effectiveness, and durability to meet your project’s specific needs. With a host of options ranging from the ubiquitous FR-4 to advanced materials designed for high-frequency applications, the journey of selecting a printed circuit board substrate is both exciting and challenging. Join us as we unravel the factors that will elevate your design from ordinary to extraordinary.

Choosing the appropriate substrate for your printed circuit board (PCB) project is a critical step that greatly impacts the final product’s performance, durability, and cost-effectiveness. Different types of substrates serve various applications, and understanding their characteristics and applications can guide you in making an informed decision.

Final Thoughts on Choosing PCB Substrates

Each substrate material exhibits unique characteristics and involves trade-offs. The decision on which to use should take into account a multifaceted array of factors, ranging from electrical properties to environmental resistance. Being informed about these variables will positively influence your PCB’s development process.

By considering all these determinants carefully, you can derive the best substrate options to meet your project requirements effectively. Additionally, innovations and trends should continually inform your choices to harness new technologies effectively.

In a landscape characterized by rapid advancements, staying updated on the latest materials and designs will foster innovation in your PCB projects.

To become adept at selecting and designing PCBs, one must also gain insights into the processes involved. For a deeper understanding of how printed circuit boards are designed and manufactured, resources like How Printed Circuit Boards Are Designed and Manufactured can offer invaluable knowledge.

Rigid Substrates

Rigid substrates are perhaps the most commonly used in the industry. They provide mechanical support and are generally made from materials like FR-4, which is known for its excellent performance, durability, and cost-effectiveness. FR-4 is a glass-reinforced epoxy laminate that balances electrical insulation, thermal properties, and fire resistance, making it the standard choice for many applications.

Choosing the right PCB substrate is a pivotal step in ensuring the success of your project. First, it’s essential to differentiate between the two primary categories: rigid and flexible substrates. Rigid substrates, often made of FR-4, dominate the market, accounting for around 80% of PCB production due to their cost-effectiveness and reliable performance. Meanwhile, flexible substrates are increasingly popular, particularly in applications demanding adaptability and lightweight designs, with growth projected at 12% annually.

Evaluating the specific needs of your application is crucial. For instance, if you expect high-temperature environments, consider materials that exhibit superior thermal stability. Fire resistance is another essential factor; FR-4 not only provides a cost-effective solution but also meets these safety standards. According to a recent study, substrates with better thermal properties can enhance signal integrity by reducing losses by up to 30%.

Finally, it’s vital to consider the fabrication process, as each substrate material demands unique handling and processing methods. For a deeper understanding, explore resources such as Understanding the Processes Involved in PCB Fabrication and learn about the latest breakthroughs in flexible materials at Innovations in Flexible PCB Technology.

Choosing the right PCB substrate is crucial for ensuring the success of your electronic project. Begin by understanding the two main categories: rigid and flexible substrates, each suited for different applications. Consider factors such as thermal management, mechanical properties, and cost-effectiveness in your selection process. The widely used FR-4 material offers a balanced approach, making it a popular choice due to its durability and performance. Always keep the application’s requirements in mind, including any specific environmental conditions the PCB will face. Lastly, don’t overlook the fire resistance of the materials, as safety is paramount in any design. By meticulously considering these aspects, you can pave the way for a successful PCB outcome.

FAQ

What are the main types of PCB substrates available?

R: The primary types of PCB substrates include rigid substrates, which provide stability and support, and flexible substrates, which offer versatility for compact designs and bending applications.

Why is FR-4 material considered a standard for PCB substrates?

R: FR-4 material is widely recognized for its excellent balance between cost, durability, and performance, making it a go-to choice for many PCB applications.

What factors should be considered when selecting a PCB substrate?

R: Key factors to consider include temperature resistance, mechanical strength, fire resistance, and the specific application requirements of your PCB project.

How does the choice of substrate affect PCB performance?

R: The right substrate can significantly impact the electrical performance, signal integrity, and overall reliability of the PCB, influencing its effectiveness in the final product.

When should I consider using flexible substrates over rigid ones?

R: Consider using flexible substrates when your design requires bendability, lightweight, or tight space constraints, such as in wearable technology or compact electronic devices.