|

IN BRIEF

|

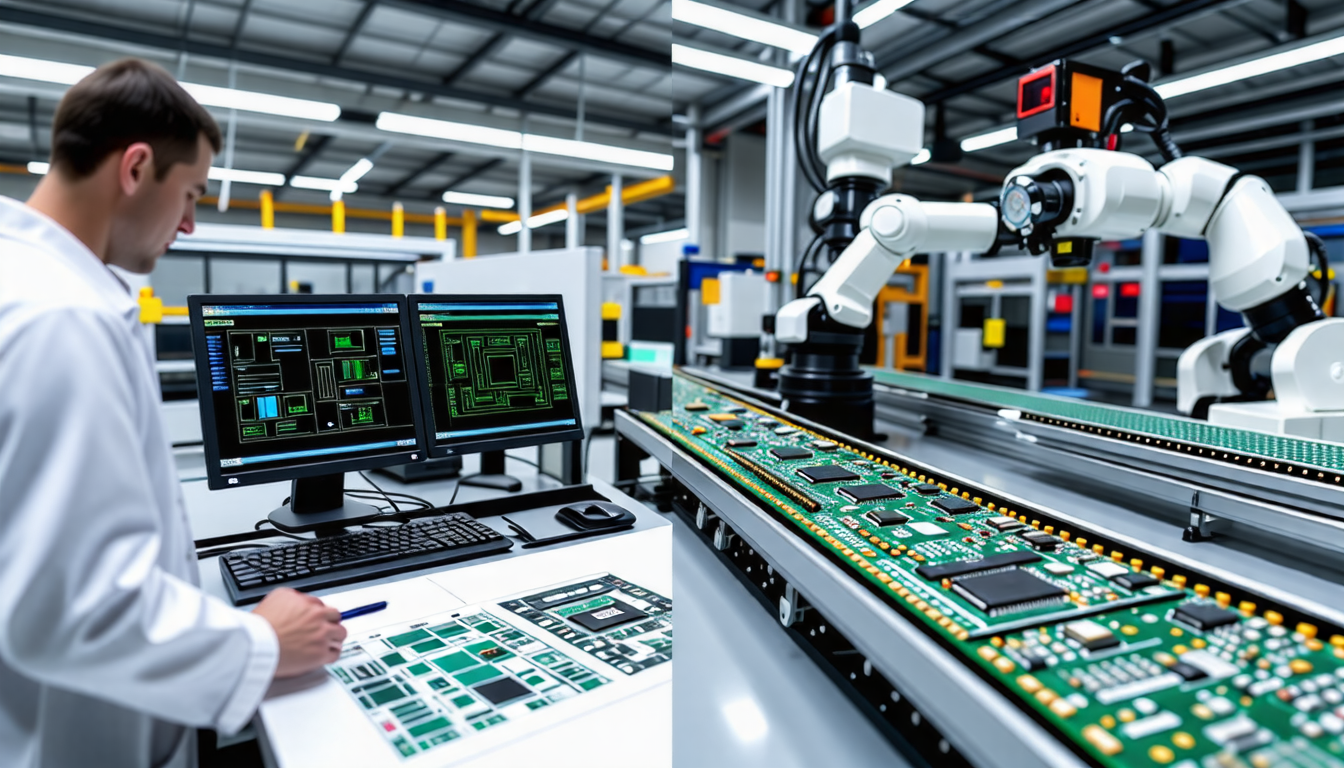

In the fast-paced world of electronics, the journey from a mere concept to a functional product is exhilarating yet challenging. To navigate this landscape, effective prototyping is the cornerstone of success. Imagine transforming your imaginative ideas into tangible devices that not only meet market demands but also revolutionize user experiences. The prototyping process demands creativity, precision, and an understanding of end-user needs. By crafting prototypes that evolve through iterations, you ensure that each step brings your vision closer to reality. Embrace simplicity at the beginning, utilizing readily available components to kickstart the journey. This guide unveils the essential techniques and insights for perfecting your electronic product prototype, setting the stage for groundbreaking innovation!

Prototyping is a vital stage in the development of electronic products. It transforms ideas into tangible forms, allowing for testing and refinement before final production. A systematic approach ensures that each phase of prototyping is executed efficiently, minimizing costs and maximizing the chances of market success.

Post-Launch Iteration

Post-launch, the journey does not end. Continuous feedback from users will help you identify areas for improvement. Plan for periodic updates based on user experiences and new technological advancements within the industry.

This ongoing process of innovation is essential for keeping your product relevant in a fast-paced technological landscape. Tracking user engagement and collecting data over time will nourish future iterations or completely new product lines, ultimately contributing to sustained business success.

Choosing the Right Prototyping Method

Once you have a clear understanding of user needs, the next step is to choose an appropriate prototyping method. Here are a few commonly used techniques:

Low-Fidelity Prototyping

Low-fidelity prototypes are typically simple and inexpensive. They can be made from cardboard, paper, or even basic electronic components arranged on a breadboard. Such prototypes are beneficial for illustrating general design concepts without delving into intricate technical details.

Prototyping a new electronic product is a multifaceted process that requires thoughtful planning and execution. Initially, it’s crucial to focus on understanding the target audience’s needs. In fact, according to recent surveys, 70% of successful prototypes stem from thorough user feedback, highlighting its importance. Once the needs are identified, brainstorming various potential designs is essential. It’s recommended to narrow down options to around three viable concepts, allowing for effective comparison and assessment.

Following ideation, the choice of prototyping methods can significantly affect outcomes. Starting with a simple approach, such as utilizing breadboards or modules, allows for cost-effective and rapid iteration. Research indicates that projects that use basic prototyping can reduce development time by up to 30%. As you progress, transitioning to more complex prototypes, like those incorporating custom PCBs, will enhance functionality and reliability.

Moreover, key steps in the prototyping process include designing the circuit schematic and selecting the right components. With an emphasis on testing throughout each stage, developers can identify flaws early, thereby saving valuable resources. Ultimately, a structured approach to prototyping not only drives innovation but also accelerates time-to-market.

Effective prototyping of a new electronic product is a dynamic journey that requires creativity and precision. Start by understanding the users’ needs, as their feedback will guide your design choices. Initiate the process with simple, cost-effective solutions such as breadboards and modular components, allowing for quick iterations and tangible results. Gradually transition to custom PCB designs, ensuring every iteration moves you closer to your final product vision. Throughout this journey, remember to maintain flexibility in your approach—embrace feedback, learn from each model, and refine your ideas accordingly. Ultimately, the prototyping process is not just about the end result; it’s about fostering innovation, collaboration, and growth in your ideas.

FAQ

What are the initial steps to prototype a new electronic product?

R: Begin with a thorough understanding of user needs. Then, brainstorm various ideas, sketch them, and refine your list to a few top contenders before moving to the prototyping stage.

How important is it to create a schematic diagram?

R: Creating a schematic diagram is crucial as it visually represents the circuit connections and helps ensure that your design functions as intended before physical creation.

What prototyping methods should I consider?

R: Start with the simplest and most economical methods, such as using breadboards and modules. As you iterate, progress to more complex techniques like custom printed circuit boards (PCBs) to enhance functionality.

How do I ensure the prototype effectively meets user requirements?

R: Conduct thorough user testing and gather feedback at various stages of the prototyping process. This will help align the product with user expectations and address any issues early on.

What are the key components I should select for my prototype?

R: Choosing the right components involves evaluating functionality, availability, and compatibility. Researching components that have proven reliability and can withstand an iterative design process is essential for a successful prototype.