|

IN BRIEF

|

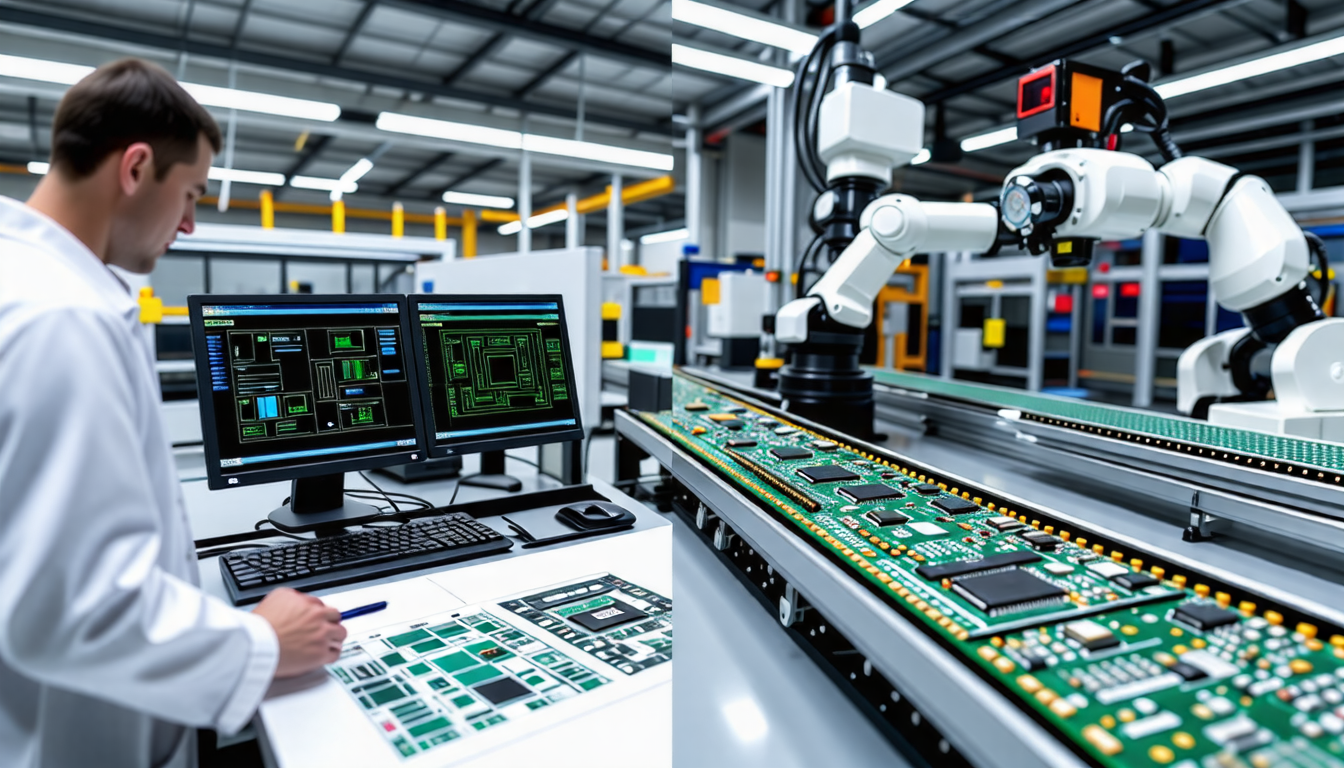

In the fast-paced world of technology, the ability to efficiently scale up production for new electronic products is paramount for success. As market demands shift and consumer expectations skyrocket, engineers and manufacturers must embrace innovative strategies that blend cutting-edge techniques with cost-effectiveness. Imagine a landscape where automation minimizes human error, and seamless integration of supply chain partners propels your production forward. This journey begins with a keen understanding of quality control and a solid grasp of budget allocations. From introducing smart automation to ensuring the procurement of reliable components, every decision can accelerate your path to thriving in a competitive market. It’s time to unlock the full potential of your manufacturing process, paving the way for groundbreaking electronic innovations.

Scaling up production for new electronic products demands a meticulous approach that blends innovation with systematic processes. It’s not just about increasing output but doing so in a way that maintains high-quality standards and ensures operational efficiency. This article explores the fundamental aspects needed to enhance production capabilities in the electronics sector.

Regular Risk Assessments

Conducting regular risk assessments within your scalable production framework is essential to anticipate and mitigate challenges. Identifying potential risks—whether they stem from material shortages, market fluctuations, or logistical challenges—enables proactive planning.

Creating contingency plans ensures that your production scales smoothly, even in the face of unforeseen obstacles. This approach minimizes disruptions that could hinder growth and maintains production schedules.

Training and Empowering Your Team

A skilled workforce is essential for maintaining quality. Providing regular training for your employees on the latest production techniques and quality standards instills a culture of excellence. Empowering teams to take ownership of their processes enhances accountability and encourages innovation.

Scaling up production for new electronic products requires a meticulous approach to ensure both efficiency and quality. First and foremost, it is essential to gain control over your quality management processes. Statistics show that quality issues can lead to a staggering 20% increase in overall production costs, which can be detrimental when aiming for large-scale output.

Moreover, understanding your cost structure is vital. By effectively budgeting for materials, labor, and overhead, companies can optimize their resources. Recent studies indicate that integrating a robust financial plan can enhance profitability by as much as 15%, allowing businesses to operate within their means while meeting production targets.

Transitioning to automation is another critical factor. By implementing automated systems, manufacturers can reduce human error and increase production speed significantly. For instance, factories that have embraced automation report a productivity increase of up to 50%, which is a game-changer in the fast-paced electronics market.

Lastly, sourcing reliable components ensures the durability and efficacy of products, directly impacting customer satisfaction and long-term sales. By focusing on these key areas, companies can navigate the complexities of scaling production successfully.

Scaling up production for new electronic products is a multifaceted challenge that demands a strategic approach. First and foremost, it is essential to establish a solid quality control system to ensure that every product meets high standards, preventing costly recalls and maintaining customer satisfaction. Additionally, understanding cost structures plays a critical role; accurate insight into expenses allows for better decisions on resource allocation. Embracing automation can significantly enhance efficiency, reducing manual errors and speeding up the production timeline. Finally, sourcing reliable components is key to maintaining product integrity as production scales. By addressing these areas, manufacturers can not only boost output but also sustain quality in a competitive market.

FAQ

What are the key factors for efficiently scaling up production of new electronic products?

R: The key factors include establishing quality control processes, understanding cost structures, implementing automation, and sourcing reliable components from suppliers.

How can automation help in increasing production capacity?

R: Automation minimizes human error, speeds up processes, and reduces manual labor, allowing for greater production efficiency and consistency in electronic manufacturing.

What should I consider when managing my budget for scaling production?

R: Proper budget allocation is crucial. You need to balance expenses on materials, labor, and operational costs while ensuring there’s enough investment for scaling operations effectively.

Why is partnering with contract manufacturers beneficial for scaling?

R: Partnering with contract manufacturers or electronic manufacturing services (EMS) enables companies to leverage economies of scale, reduce capital expenditures, and increase production capabilities without significant upfront investments.

What are the common challenges faced in electronic production scaling?

R: Common challenges include maintaining quality control during increased output, addressing cash flow issues, and ensuring that the necessary infrastructure is in place to support expansion efforts.