|

IN BRIEF

|

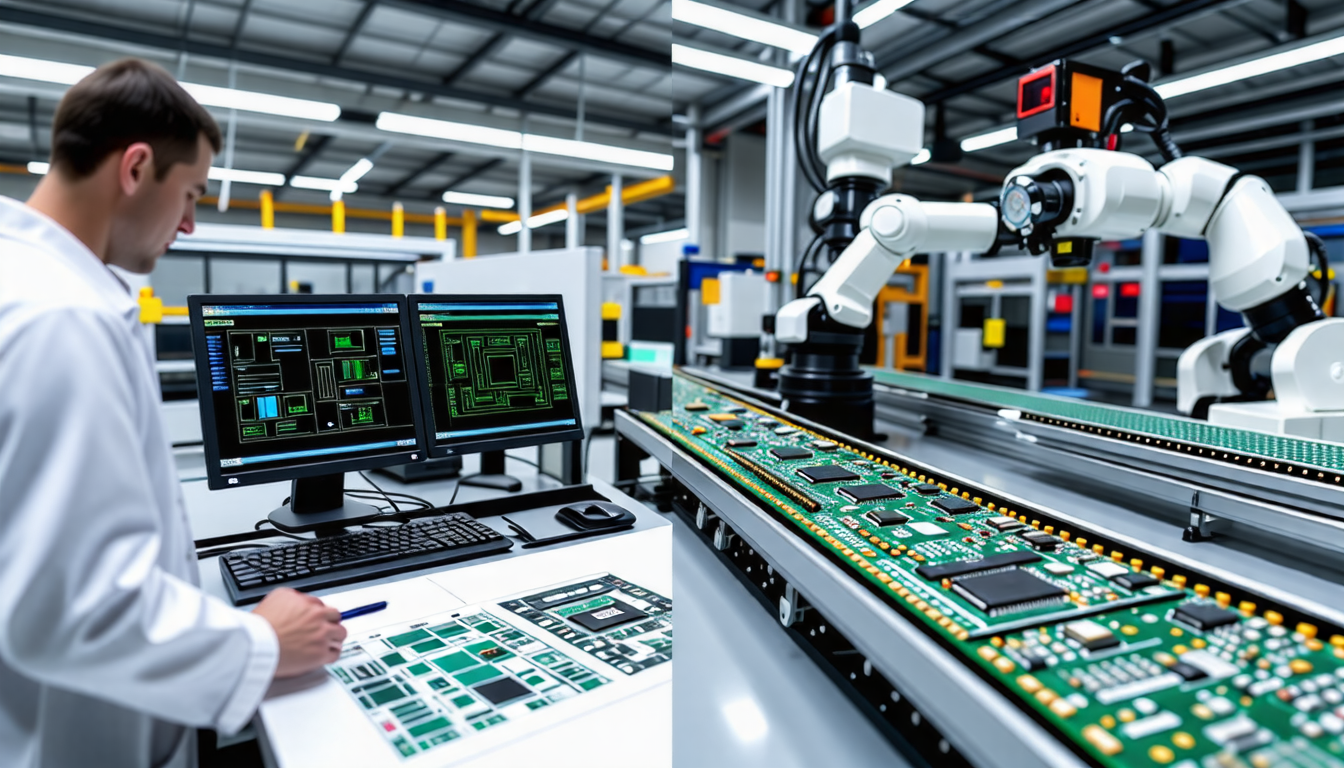

In the rapidly evolving landscape of electronics manufacturing, compliance with international standards stands as a vital pillar for success. Companies striving for global recognition and market penetration must navigate a complex web of regulations that govern everything from safety performance to environmental impact. The stakes are high; a misstep can lead to costly delays or even product recalls. So, how can manufacturers ensure that every component, circuit board, and product design adheres impeccably to the mandated criteria? By integrating rigorous testing procedures, fostering an ethical sourcing strategy, and embedding compliance measures into the design phase, businesses can not only meet but exceed these standards. As we delve deeper into this topic, we’ll uncover practical strategies and insights for navigating the compliance maze with confidence.

Understanding International Electronics Standards

Complying with international electronics standards is crucial for ensuring product safety, reliability, and performance in the global market. These standards serve as benchmarks against which electronic products are evaluated, safeguarding both consumers and manufacturers alike.

The Importance of Compliance

Compliance with international standards not only enhances product quality but also opens avenues for global trade. As products traverse borders, meeting recognized criteria instills trust in consumers and regulatory bodies. Furthermore, adherence to these standards reduces the risk of recalls, enhances brand reputation, and increases customer satisfaction.

Key International Standards to Consider

A wealth of standards exist across different regions and industries. A few significant ones include:

- IEC (International Electrotechnical Commission): Governing a wide range of electrical and electronic technologies.

- ISO (International Organization for Standardization): Providing guidelines in various sectors, including quality management systems.

- UL (Underwriters Laboratories): Focused on product safety standards for electrical devices.

- EN (European Norms): Standards that ensure products within the European Economic Area meet safety and performance criteria.

Familiarity with these standards can foster strategic planning for compliance in electronic product development.

Establishing Internal Processes for Compliance

Creating an internal compliance framework is essential. A methodical approach not only ensures that every product aligns with necessary regulations, but also streamlines the development process, making it more efficient.

Developing a Compliance Team

A dedicated team responsible for compliance activities ensures that your organization meets relevant standards. This team should consist of members from design, engineering, quality assurance, and legal departments. Collaborative efforts yield an in-depth understanding of compliance requirements and assist in identifying potential pitfalls early in the product development cycle.

Implementing Training Sessions

Training is vital for keeping your team updated about the latest standards and regulations. Regular workshops enhance the team’s skill set while promoting a culture of compliance throughout the organization. Moreover, ensuring that all personnel involved in product development understand the importance of these standards fosters a unified approach to compliance.

Designing with Compliance in Mind

Product design plays a pivotal role in adherence to standards. By incorporating compliance measures early in the design phase, manufacturers can navigate complex regulations more efficiently.

Utilizing Simulation Software

Equipping your design team with simulation software helps predict and resolve potential compliance issues during the development phase. This proactive approach minimizes design changes later in the process, reducing delays and ensuring that the final product adheres to required standards.

Conducting Risk Assessments

Integrating risk assessment methodologies into your design process allows teams to identify vulnerabilities early. Evaluating potential safety hazards and electrical failures aids in the development of safer products. This diligence not only aligns with compliance requirements but also enhances the user experience.

Documentation and Testing Procedures

Accurate documentation and thorough testing are crucial steps in ensuring compliance with international electronics standards. Adequate records of tests and evaluations demonstrate adherence to regulations, offering transparency in the production process.

Establishing Testing Protocols

Developing comprehensive testing protocols ensures that every aspect of the product is scrutinized before launch. These protocols should align with relevant standards, detailing specific tests for durability, safety, and functionality. Regular checks and validation procedures keep the production process on track, mitigating risks of non-compliance.

Documenting Compliance Efforts

Creating a meticulous record of compliance activities greatly enhances accountability. Documentation should include testing results, certifications received, and any nonconformities addressed. This extensive record set showcases commitment to compliance and aids in navigating audits or inspections.

Collaborating with External Partners

Working with external partners, including component suppliers and regulatory bodies, can enhance compliance efforts significantly. A robust collaborative approach allows for sharing knowledge and resource optimization.

Sourcing Components Ethically

When sourcing components, it is essential to ensure that suppliers adhere to ethical practices and comply with relevant standards. Striving to source components ethically fosters trust and sustainability throughout the supply chain. Check out strategies on how to source components ethically for your manufacturing processes.

Engaging Third-Party Testing Facilities

Incorporating third-party tests helps validate compliance claims. These agencies perform evaluations against relevant standards, offering an unbiased perspective on product safety and performance. Leveraging their expertise can bolster the credibility of your products in the marketplace.

Staying Updated with Regulations

International electronics standards are subject to changes and updates. Keeping abreast of these modifications is vital to maintaining compliance.

Regular Review of Standards

Periodic reviews of applicable standards ensure that your team remains knowledgeable about changes influencing product development. Subscribing to newsletters and attending industry conferences can keep your organization aligned with the latest practices and requirements.

Utilizing Regulatory Databases

Many organizations maintain decentral databases that offer updated information on regulations and standards. Leveraging these resources can help your compliance team stay informed and proactively adjust processes to align with changes effectively.

Understanding Product Safety Standards

Adhering to product safety standards is paramount in the electronics sector. Understanding these standards can guide you in producing safe and reliable products.

Risk Management Techniques

Implementing risk management techniques ensures that potential hazards are identified and mitigated throughout the product lifecycle. Strategies include rigorous testing, quality control processes, and user feedback loops designed to capture data on product performance post-launch.

Engaging with Regulatory Authorities

Fostering relationships with regulatory bodies allows for clearer communication regarding compliance expectations. Engaging with these entities creates opportunities for ongoing support and guidance, ultimately leading to better compliance outcomes.

Automating Compliance Processes

The integration of automation technologies can dramatically enhance compliance management. Implementing software solutions tailored for compliance monitoring streamlines operations and reduces human error.

Utilizing Compliance Management Software

Employing compliance management software can facilitate easier tracking of standards and internal practices. Such tools often include features like tracking changes in regulations, documenting testing protocols, and managing supplier compliance. This technology enforces accountability and encourages adherence across departments.

Real-time Monitoring for Compliance

Utilizing real-time monitoring tools can assist businesses in identifying potential issues promptly. These tools provide insights into production processes, quality control metrics, and compliance-related activities, enabling swift adjustments to maintain standards.

Addressing Non-compliance Issues

Even with careful planning and execution, non-compliance issues can arise. Understanding how to effectively manage these situations is crucial for maintaining product integrity.

Developing a Contingency Plan

A well-defined contingency plan prepares your team for addressing non-compliance issues swiftly. This plan should include assessment procedures, corrective actions, and communication strategies to inform stakeholders of necessary changes.

Learning from Non-compliance Events

Each instance of non-compliance provides an opportunity for growth. Conducting detailed analyses of non-compliance events can reveal weaknesses in your processes and lead to the development of improved strategies moving forward. This reflective approach tightens your compliance framework and strengthens future operations.

The Intersection of Compliance and Innovation

While compliance is crucial, it should not stifle innovation. Striking a balance between adhering to regulations and fostering creativity can lead to breakthroughs in electronics design.

Encouraging Innovative Practices

Pursuing innovative practices within a compliance framework encourages teams to think outside the box. Monitored experimentation within set guidelines can yield exciting advancements in electronic products while aligning with required standards.

Collaboration Between Compliance and R&D Teams

Facilitating communication between compliance and research & development teams allows innovators to remain mindful of regulatory constraints. Early involvement of compliance personnel in the design process ensures that creative solutions do not compromise standards while spurring innovations for future products. The integration of technology in areas such as online gambling is a pertinent example of how the gaming industry is adapting, evident in the rise of live dealer casinos. Explore how this technology changes online gambling here.

Cultivating an Organizational Culture of Compliance

Ultimately, a culture of compliance encompasses the entire organization. It transforms compliance efforts from being seen as a burden into an inherent part of the company’s ethos.

Promoting Awareness and Responsibility

Embedding compliance principles into the company culture promotes collective responsibility throughout all levels of the organization. Initiatives such as compliance awareness campaigns or incentive programs can motivate all team members to prioritize compliance in their daily operations.

Reinforcing Leadership Commitment

Leadership should lead by example in fostering a culture of compliance. Their active participation in compliance initiatives and open discussions about challenges creates a transparent environment where compliance is prioritized, ensuring collective accountability and awareness.

Measuring Success in Compliance Efforts

Establishing benchmarks to measure compliance success is vital for ongoing improvement.

Performance Metrics

Developing performance metrics allows your organization to evaluate the effectiveness of compliance initiatives. Metrics may include rates of compliance adherence, timelines for meeting regulatory changes, and the frequency of non-compliance incidents.

Continuous Improvement Approaches

Utilizing gathered metrics leads to constant enhancement of compliance processes. Engaging in regular reviews based on performance feedback can help fine-tune strategies, ensuring compliance remains relevant and effective in an ever-evolving landscape.

Ensuring compliance with international electronics standards is essential for manufacturers navigating today’s competitive landscape. With the global electronics market projected to reach approximately $2 trillion by 2024, adherence to standards like IEC, ISO, and UL is crucial for maintaining market relevance and consumer trust.

First, it is important to understand that electronic product safety requirements vary by region. For instance, the European Union mandates compliance with the CE marking, whereas the United States relies on UL certification. Companies must stay abreast of these differences and ensure that their products meet the necessary criteria in each target market. Utilizing resources, such as understanding international standards, can significantly streamline this process.

Moreover, incorporating testing procedures, as outlined in common testing guidelines, enhances product development cycles. Regular audits and assessments further reinforce compliance, identifying potential issues before they escalate. Lastly, fostering an organizational culture that prioritizes ethical manufacturing can serve as a foundation for compliance, given the rising importance of ethical sourcing and consumer awareness in today’s economy.

In today’s rapidly evolving electronics landscape, ensuring compliance with international standards is paramount for organizations striving for excellence. By adopting a proactive approach, manufacturers can navigate the intricate web of global regulations with ease. This includes fostering a culture of quality assurance, integrating testing procedures early in the design process, and staying updated with changes in legislation. Collaboration with industry experts and leveraging advanced technologies can also streamline compliance efforts. Furthermore, continuous training of teams on regulatory requirements enhances their ability to identify and mitigate compliance risks. Ultimately, prioritizing standardization not only secures consumer trust but also paves the way for innovation in the electronic realm.

FAQ

What are the key international electronics standards I need to be aware of?

R: The essential international electronics standards include IEC 60950 for safety, ISO 9001 for quality management, and RoHS for materials compliance. Understanding these standards ensures your products meet safety and environmental requirements.

How can I stay updated on changes to electronics standards?

R: Regularly monitor publications from organizations like the International Electrotechnical Commission (IEC) and participate in industry forums or workshops to keep abreast of any updates or revisions to existing standards.

What steps should I take to test my products for compliance?

R: Begin by conducting a thorough risk assessment to identify potential compliance issues. Follow this by performing necessary testing procedures and documenting results. Collaborating with certified laboratories can also facilitate this process.

How can I effectively train my team on compliance requirements?

R: Organizing regular training sessions that focus on compliance regulations and standard practices is crucial. Consider inviting external experts or utilizing online training modules to enhance your team’s understanding of these standards.

What are the consequences of non-compliance with electronics standards?

R: Failing to comply with international electronics standards can lead to significant repercussions, including legal issues, product recalls, and damage to your company’s reputation. It is vital to prioritize compliance to minimize risks associated with your products.