|

IN BRIEF

|

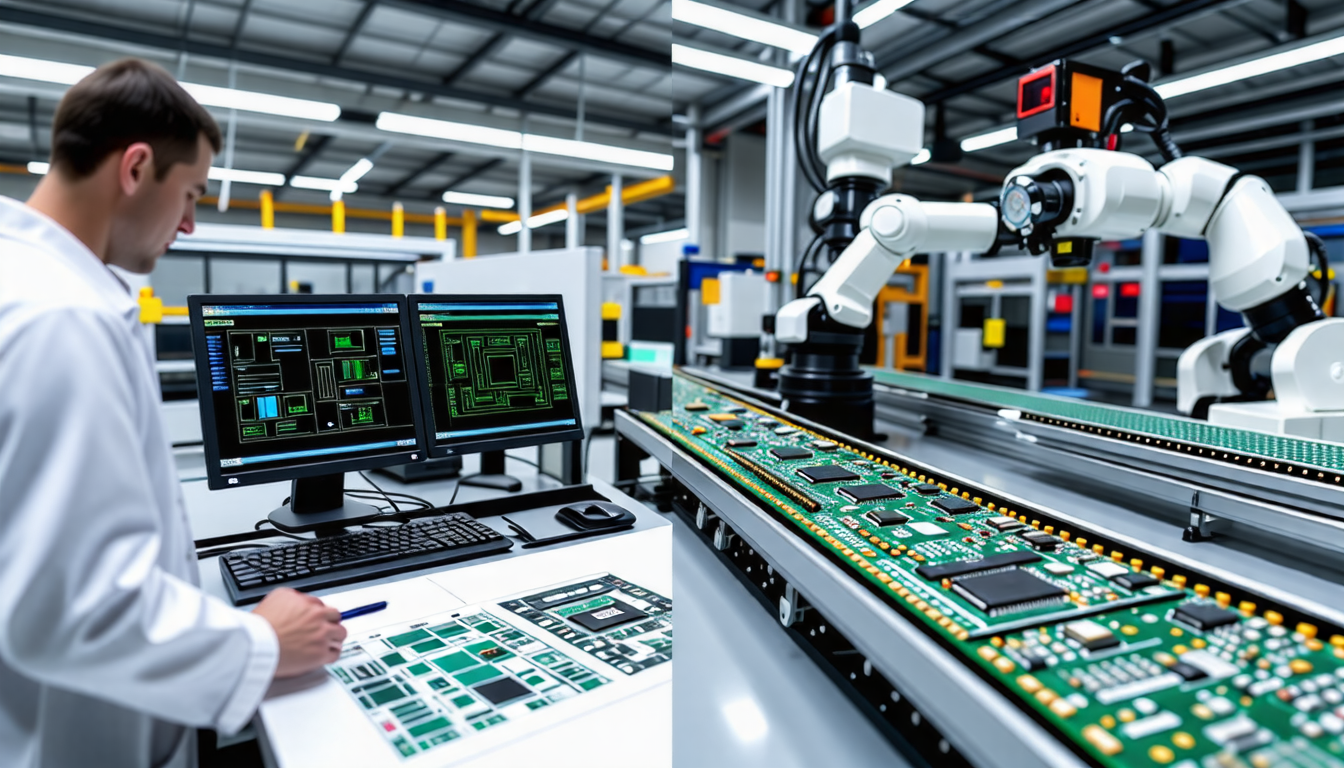

In the intricate dance of electronics manufacturing, sourcing components ethically emerges as a vital step, transcending mere responsibility to become a hallmark of innovation. Imagine a world where the components powering our gadgets not only display cutting-edge technology but also embody values of sustainability and ethics. This exciting journey begins with a commitment to forging relationships and cultivating partnerships that prioritize not only quality but also the welfare of communities and the environment. Gone are the days when profitability overshadowed ethical considerations; today, the quest for ethical electronics drives companies to reevaluate their supply chains, ensuring that every silicon chip and copper wire is sourced with care. Dive into the world of ethical components and uncover the transformative approaches that are reshaping the future of technology.

Understanding Ethical Sourcing in Electronics Manufacturing

Sourcing components ethically in electronics manufacturing goes beyond mere compliance; it requires a comprehensive understanding of the supply chain, the materials involved, and the implications of sourcing decisions on global communities. By analyzing every aspect of the production process, manufacturers can ensure that their components are not only high quality but also socially responsible and environmentally sustainable.

The Importance of Ethical Sourcing

In today’s world, consumers are increasingly aware of ethical issues associated with electronics production. The rise of conscious consumerism has led to a demand for transparency and accountability from manufacturers. Ethical sourcing plays a significant role in maintaining brand reputation. By cultivating an image of responsibility, businesses can build trust with their customers, ultimately influencing purchasing decisions.

Assessing Supply Chain Transparency

Establishing transparent supply chains is essential for ethical sourcing. Manufacturers should collaborate with suppliers who are willing to provide visibility into their production processes. By obtaining detailed insights into sourcing practices, including labor conditions and raw material origins, companies can better understand potential risks associated with their supply chains. Furthermore, engaging in direct conversations with suppliers can highlight areas for improvement and foster stronger partnerships.

Establishing Supplier Relationships

Strong relationships with suppliers are crucial for ethical sourcing. Building trust can facilitate better communication regarding sourcing practices and help reduce the risk of unethical behavior within the supply chain. Furthermore, long-term partnerships often lead to improved collaboration on sustainability initiatives, benefiting both parties. Consider organizing regular meetings to discuss business objectives, ethical standards, and any challenges that may arise.

Identifying Ethical Sourcing Standards

One of the fundamental aspects of ethical sourcing is the identification and implementation of clear guidelines. Manufacturers should establish a set of standards that reflect their commitment to ethical practices. This includes defining expectations regarding labor rights, environmental impact, and material sourcing. By creating a robust ethical sourcing policy, companies can demonstrate their seriousness in pursuing responsible manufacturing.

Certifications to Consider

Various certifications can aid manufacturers in their pursuit of ethical sourcing. For instance, the TCO Certified label indicates that products fulfill specific criteria related to design, manufacturing conditions, and the use of conflict minerals. Similarly, the Fair Trade certification ensures that producers receive equitable compensation and work in safe conditions. By seeking out suppliers with these certifications, companies can confidently align their sourcing practices with ethical standards.

Implementing Sustainable Practices

Sustainability should be at the forefront of ethical sourcing efforts. This entails not only selecting eco-friendly materials but also reducing waste and minimizing the overall environmental impact of production. Manufacturers can implement greener practices by using renewable energy sources, employing efficient manufacturing techniques, and reducing packaging materials. These sustainable actions contribute to environmental conservation while also appealing to eco-conscious consumers.

Evaluating Raw Material Sources

Raw materials play a significant role in electronics production. Sourcing materials like silicon, copper, and other metals responsibly is vital for minimizing environmental harm. Manufacturers should look for suppliers who practice responsible mining and ensure that the extraction process does not contribute to habitat destruction or human rights abuses. Exploring recycled or reclaimed materials can also provide a sustainable alternative, decreasing reliance on virgin resources.

Navigating the Challenges of Sourcing

Despite good intentions, ethical sourcing often comes with challenges. Many companies rely on third-party suppliers, making it difficult to monitor their practices effectively. The lack of direct oversight can lead to unintentional complicity in unethical behavior. Therefore, manufacturers must actively engage in risk assessment and mitigation strategies to address these concerns.

Conducting Supplier Audits

Regular supplier audits should be an integral part of any ethical sourcing strategy. By evaluating suppliers against the established guidelines and ethical standards, manufacturers can identify areas of concern and implement necessary improvements. Audits can range from internal assessments to independent evaluations conducted by third-party organizations. Transparency throughout the audit process fosters accountability among suppliers, encouraging adherence to ethical practices.

Educating Stakeholders

Education is a powerful tool for instilling values surrounding ethical sourcing. All stakeholders, including employees, suppliers, and customers, should understand the significance of sourcing components responsibly. Manufacturers can provide training programs, workshops, and informational resources to promote awareness and engagement with ethical sourcing initiatives

Building Awareness Among Consumers

Moreover, educating consumers about ethical sourcing can elevate their purchasing decisions. By communicating the benefits and importance of ethical electronics, manufacturers can foster a sense of loyalty among customers who prioritize sustainability and social responsibility. Engaging marketing campaigns and transparent storytelling can highlight a company’s mission, inviting customers to participate in the ethical sourcing journey.

Utilizing Technology in Sourcing

Technology can significantly enhance the sourcing process, making it easier for manufacturers to identify ethical suppliers and materials. Various digital platforms offer resources for tracking sustainability and ethical sourcing practices. Utilizing these tools can streamline the procurement process and assist companies in making informed decisions.

Leveraging Data Analytics

Data analytics can provide valuable insights into supply chain performance, enabling manufacturers to identify potential risks and opportunities for improvement. By analyzing trends and supplier performance metrics, companies can strengthen their sourcing strategies and enhance overall efficiency. This proactive approach fosters a more ethical supply chain and can lead to significant economic benefits in the long run.

Maintaining Accountability

Establishing accountability mechanisms is essential for ensuring compliance with ethical sourcing practices. Manufacturers should create internal review processes to monitor their suppliers and evaluate their adherence to established standards. Regular reporting and feedback loops can provide opportunities for improvement, allowing stakeholders to collaborate more effectively.

Creating a Feedback Culture

A culture of feedback encourages continuous improvement within the organization. Employees and stakeholders should feel comfortable voicing concerns or suggesting enhancements related to ethical sourcing practices. Establishing clear channels for communication will help to identify potential challenges early on and foster a supportive environment committed to ethical standards.

Engaging in Industry Collaborations

Collaborating with industry peers can serve as an innovative approach to addressing common sourcing challenges. By joining forces with other manufacturers, businesses can share best practices, develop industry standards, and contribute to a more sustainable ecosystem. Additionally, these partnerships can facilitate dialogues around ethical issues that often arise in electronics manufacturing.

Participating in Ethical Initiatives

Many organizations and initiatives dedicate themselves to promoting ethical sourcing in the electronics sector. Manufacturers can engage with these groups, participate in discussions and contribute to the development of social and environmental best practices. Being part of a collective effort enhances a company’s ability to effect positive change across the industry.

Continuously Evolving Ethical Standards

As society and technology evolve, so do the challenges and expectations surrounding ethical sourcing. Manufacturers must remain agile and prepared to adapt their strategies accordingly. Staying informed about emerging trends, regulatory changes, and consumer preferences allows companies to refine their ethical sourcing practices, ensuring ongoing compliance and alignment with evolving standards.

Investing in Research and Development

Investment in research and development can yield innovative solutions for ethical sourcing challenges. By exploring new materials, processes, and methodologies, manufacturers can optimize their production methods while adhering to ethical practices. Dedicating resources to R&D demonstrates a commitment to a sustainable future and positions companies as leaders in their field.

Measuring Success in Ethical Sourcing

Measuring the impact of ethical sourcing initiatives is crucial for assessing progress and identifying areas for improvement. Manufacturers should establish benchmarks and key performance indicators to track their efforts effectively. Periodic evaluations can provide insights into successes and challenges, informing future strategies to enhance ethical sourcing efforts.

Setting Realistic Goals

Setting realistic, achievable goals for ethical sourcing initiatives helps maintain momentum and focus. Manufacturers should ensure that goals are specific, measurable, and time-bound, providing a clear roadmap for progress. Regularly reviewing these objectives can foster accountability and adaptation, allowing companies to refine their approaches in response to emerging challenges.

In the world of electronics manufacturing, sourcing components ethically is becoming increasingly vital. With the global market shifting towards sustainability, manufacturers must prioritize ethical sourcing and consider the impacts of their supply chains. A recent study indicated that over 60% of consumers are willing to pay more for eco-friendly products, pushing companies to reevaluate their sourcing decisions.

One approach is establishing clear guidelines for sustainable practices. Companies can begin by auditing their supply chains to identify potential areas of improvement. For example, many manufacturers rely heavily on third-party suppliers, which can introduce risks related to worker exploitation and environmental degradation. By fostering direct relationships with suppliers, businesses can ensure compliance with ethical standards and reduce their reliance on questionable sources.

Moreover, investing in ethical technology brands and seeking out TCO-Certified components can also elevate a company’s credibility. Products that meet these stringent requirements usually have been designed with respect for workers’ rights and environmental concerns. Thus, manufacturers have the opportunity not only to enhance their brand image but also to contribute positively to the planet and society.

Ultimately, creating a transparent supply chain is essential. As manufacturers explore options for ethically sourcing electronic components, the focus should remain on building resilience and sustainability within the industry.

In the quest for ethical sourcing in electronics manufacturing, businesses must prioritize transparency and responsibility throughout the supply chain. By establishing robust guidelines that emphasize sustainability, manufacturers can align their practices with the growing demand for eco-friendly products. Collaborating closely with suppliers who share a commitment to ethical standards is crucial in minimizing risks associated with unethical practices. Implementing thorough audits and assessments will ensure that components are sourced responsibly, from the raw materials like silicon and copper to the final assembly. Ultimately, the journey towards ethical electronics not only fosters a safer environment but also enhances brand reputation and consumer trust, creating a win-win scenario for both the planet and businesses.

FAQ

What does ethical sourcing mean in electronics manufacturing?

R: Ethical sourcing in electronics manufacturing refers to the practice of acquiring materials and components in a way that respects both the environment and human rights. It involves ensuring that the materials come from sources that do not exploit workers or degrade the planet.

How can I identify eco-friendly electronic components?

R: To identify eco-friendly electronic components, look for certifications such as TCO-Certified, which indicate compliance with standards related to design, manufacturing, and ethical labor practices. Additionally, checking the brand’s commitment to sustainability is essential.

What are the challenges in sourcing ethical electronic components?

R: The main challenges include limited availability of ethically produced components, higher costs associated with sustainable materials, and navigating complex supply chains that often involve third-party suppliers with varying practices.

Can automated production ensure ethical standards?

R: While automation can reduce the likelihood of exploitative labor conditions in manufacturing, it does not guarantee ethical standards throughout the entire supply chain. It’s vital to conduct thorough audits and maintain transparency with suppliers to ensure comprehensive ethical practices.

What steps can manufacturers take to promote ethical sourcing?

R: Manufacturers can promote ethical sourcing by establishing clear guidelines for sustainable practices, conducting regular supplier audits, building strong relationships with reliable partners, and investing in training programs for suppliers to enhance compliance with ethical standards.