|

IN BRIEF

|

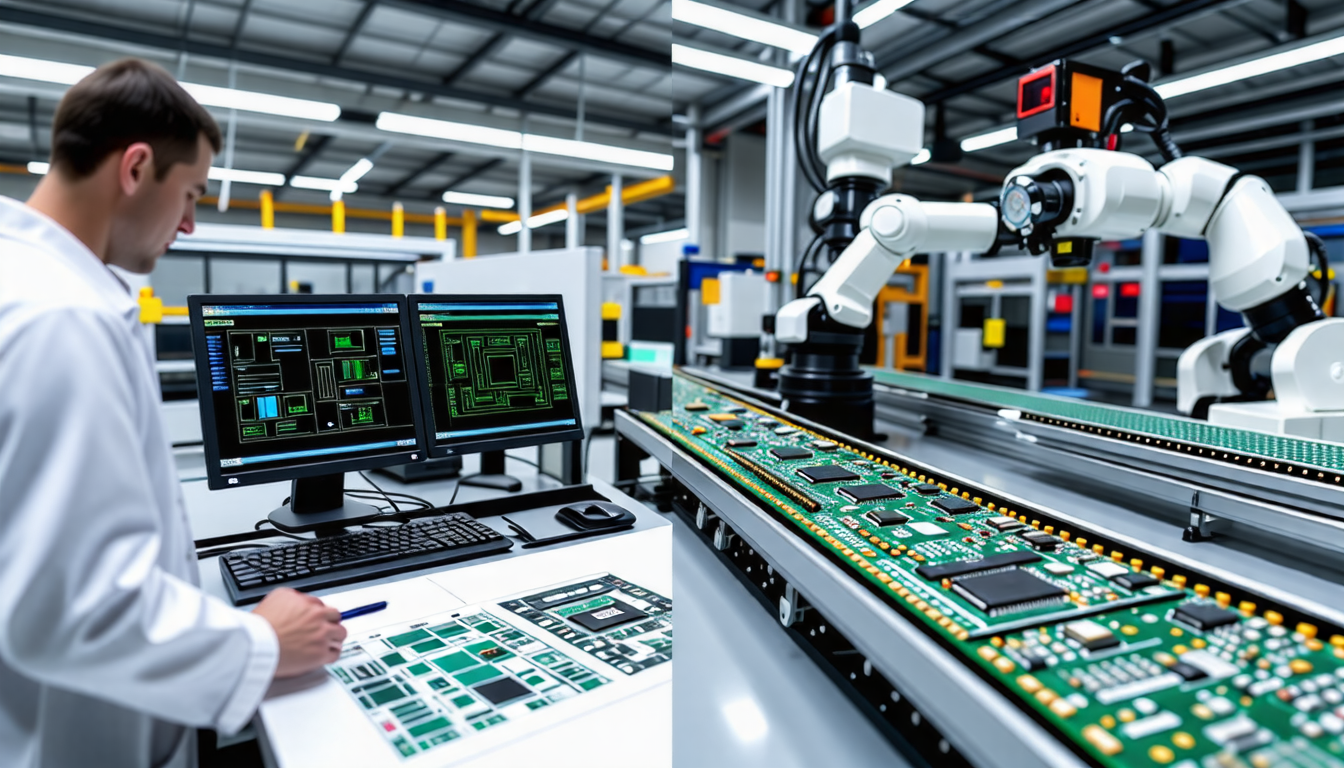

As technology continues to soar to new heights, the need for efficient and compact electronic components becomes paramount. Enter the realm of multilayer printed circuit boards (PCBs), the unsung heroes behind the sleek and powerful devices we rely on daily. These advanced circuits not only maximize design capabilities but also present a myriad of benefits that cater to the complexities of modern electronic applications. Imagine a world where space is at a premium, yet performance is uncompromised. With multilayer PCBs, engineers can reduce size without sacrificing functionality, paving the way for innovation in products ranging from smartphones to sophisticated robotics. The journey into the advantages of multilayer board designs is bound to inspire creativity and elevate potential in engineering.

With the rapid advancement of technology, multilayer PCBs have emerged as a vital component in modern electronic device design. Their unique construction allows for intricate circuit layouts, which are crucial in today’s compact and performance-driven markets. By leveraging multiple layers in their configuration, these PCBs offer numerous advantages that make them ideal for a wide array of applications.

Challenges and Considerations

While the benefits are substantial, there are inherent challenges in using multilayer PCBs. Design complexity increases with the number of layers, requiring extensive planning, careful material selection, and skilled labor for manufacturing. Potential pitfalls include misalignments during fabrication and issues related to thermal expansion. Therefore, thorough testing and validation are crucial practices to ensure optimal performance.

Additionally, the sourcing of high-quality materials and adherence to regulatory standards can have a significant impact on production costs. Keeping abreast of industry standards is essential for ensuring that products meet demanding criteria and are eligible for market distribution.

Overall, multilayer PCBs extend a plethora of advantages that are reshaping the electronics design landscape. From their compact design and lightweight nature to improved performance and cost-effectiveness, they are becoming a go-to choice for modern applications. As technology continues to evolve, the role of multilayer PCBs in enabling innovations and high-performance devices will only become more pronounced.

Weight Reduction

In addition to their space-saving benefits, multilayer PCBs contribute to a lighter overall design. The shift from multiple standard PCBs to a single multilayer board significantly reduces the weight of the final product. This is particularly advantageous in mobile electronics, where every gram counts. A lightweight device improves portability and user convenience, ultimately enhancing the user experience.

Higher Circuit Density

Another important aspect is the increased circuit density that multilayer PCBs offer. By layering multiple circuits, these boards enable intricate designs with numerous connections in close proximity. This leads to better performance because components such as capacitors, resistors, and ICs can interact with each other more effectively.

The layered construction also minimizes inductance and capacitance problems that can arise in high-frequency applications. Consequently, multilayer PCBs serve critical roles in high-performance devices, where rapid signal transmission is essential.

Improved Electrical Performance

Multilayer PCBs typically yield superior electrical performance compared to their single-layer counterparts. By allowing designers to create more efficient paths for signal and power distribution, these PCBs mitigate factors such as signal loss and interference. The reduced signal strength discrepancies contribute to better overall device performance.

Advanced methods such as EMI shielding can also be effectively integrated into multilayer designs. By strategically placing grounded layers, manufacturers can shield sensitive components from electromagnetic interference, which is increasingly important in our technology-driven world.

Optimal Thermal Management

Heat expansion can be detrimental in circuit board applications, leading to potential failures. Fortunately, multilayer PCBs are engineered to manage thermal expansion effectively. With materials specifically chosen for their low thermal expansion rates, these boards can operate under varying temperature conditions without compromising performance. Proper thermal management is especially critical in applications like automotive electronics or computing machinery, where heat buildup can and often leads to catastrophic failure.

In the realm of electronics, the integration of multilayer PCBs has become a game-changer. These advanced circuit boards, offering multiple conductive layers, enable designers to create more sophisticated electronic functionalities within a compact size. The demand for such efficiency is driven by the growing popularity of smartphones and other portable devices, where space is at a premium.

One significant advantage of multilayer PCBs is their lightweight nature. By consolidating multiple functions into a single board, they reduce the overall weight, making products easier to handle and carry. For instance, a typical multilayer PCB can weigh up to 50% less than an equivalent setup using multiple single-layer boards, translating to better user experience in portable applications.

Moreover, multilayer PCBs exhibit better performance in terms of signal integrity and electromagnetic interference (EMI) shielding. By layering, designers can strategically place power and ground planes, minimizing noise and improving circuit reliability. This is crucial for high-speed applications, as they need optimal pathways for signal transmission without disruptions. Interestingly, multilayer designs can comfortably support up to 12 layers or more, allowing unparalleled design flexibility.

Despite these advantages, it is essential to consider the initial investment and complexity involved in multilayer PCB design. However, the long-term benefits often outweigh the challenges, especially in high-tech industries pushing for greater functionality and compact designs.

In the realm of electronics, multilayer PCBs stand out as a game changer for design applications, offering unparalleled advantages that elevate performance and efficiency. Their compact size allows for smart integration within various devices, making them perfect for smartphones, computers, and other electronic products where space is at a premium. The advanced design of multilayer boards not only enhances the signal integrity but also minimizes electromagnetic interference, ensuring better overall functionality. Additionally, the ability to integrate multiple circuit paths within a single unit reduces manufacturing complexities and materials, ultimately leading to significant cost savings. These boards exemplify the essence of modern engineering innovation, providing the necessary adaptability for increasingly sophisticated electronics.

FAQ

What are the primary advantages of using multilayer PCBs in design applications?

R: The primary advantages include their compact size and lightweight design, which make them ideal for products like smartphones and computers. They also enable the integration of complex circuitry within a smaller footprint.

How do multilayer PCBs enhance performance compared to traditional PCBs?

R: Multilayer PCBs offer better performance due to their ability to distribute signal lines across different layers, reducing electromagnetic interference (EMI) and improving overall circuit functionality.

Can multilayer PCBs help in reducing manufacturing costs?

R: Yes, while the initial investment may be higher, multilayer PCBs can ultimately reduce manufacturing costs by eliminating the need for multiple single PCBs, leading to simplified assembly and less material waste.

What role does thermal management play in multilayer PCBs?

R: Multilayer PCBs typically exhibit low thermal expansion, which helps maintain performance under varying temperatures. This quality ensures that the materials used do not expand excessively when heated, preventing potential failures in the circuit.

Are there any disadvantages to using multilayer PCBs?

R: Some disadvantages include a more complex design process and potential higher manufacturing costs initially. However, these are often outweighed by the benefits they provide in terms of performance and functionality.