|

IN BRIEF

|

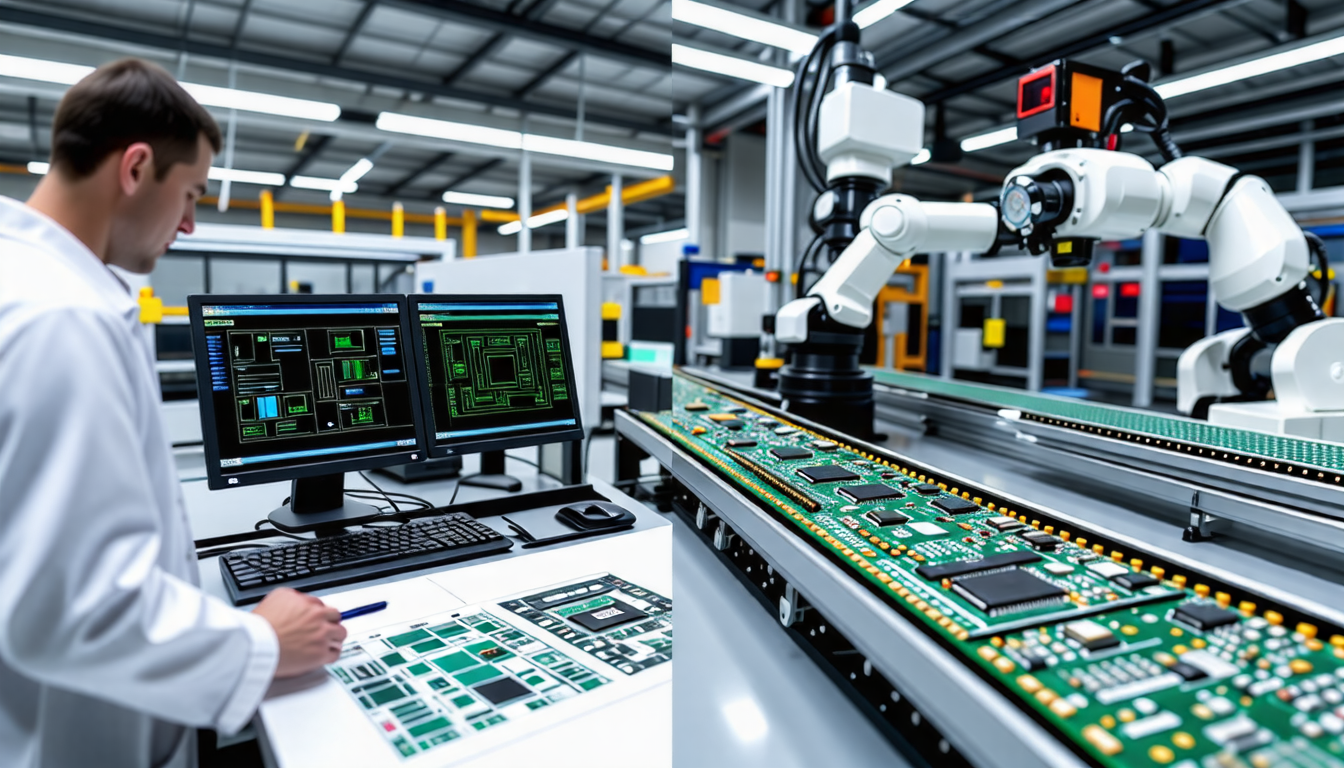

In a world increasingly driven by technology, the electronic manufacturing landscape faces a torrent of regulations that shape its very foundation. As manufacturers navigate these intricate rules, they find themselves balancing innovation with compliance, often leading to increased operational costs and complex supply chains. Each regulatory hurdle serves not only as a guide but also as a potential burden, challenging companies to innovate amidst layers of compliance. The push for eco-friendly practices further complicates the equation, demanding adherence to rigorous standards that address environmental impact. This analysis delves into the ripple effects of regulations within the electronics sector, uncovering how they influence not just compliance costs but also the drive towards sustainable manufacturing practices that ultimately shape the industry’s future.

The world of electronic manufacturing is profoundly shaped by a complex web of regulations. These rules, imposed by various governments and international bodies, are designed to protect consumers, ensure fair competition, and minimize environmental impacts. However, navigating this regulatory landscape presents significant challenges and impacts the operational costs for manufacturers across the globe.

Changing dynamics and future consequences

With a rapidly shifting regulatory environment, the impacts on electronic manufacturing are far-reaching. The interplay between regulations, consumer expectations, and technological advancements creates a challenging yet dynamic landscape. Manufacturers must maintain an adaptable and progressive approach to remain competitive while safeguarding their operations against regulatory pitfalls.

This new climate demands that manufacturers become not just compliance-oriented but innovation-driven, constantly seeking ways to enhance processes, foster collaboration, and embrace ethical practices while integrating advanced technologies. As they navigate these complexities, companies that successfully balance compliance with innovation are poised to lead the electronics manufacturing industry into a more sustainable and responsible future.

Increased costs of compliance

One of the most significant effects of regulation on electronic manufacturing is the elevation of operational costs. Meeting compliance requirements involves not only financial expenditures on materials that meet regulatory standards but also on processes and technologies that can monitor and assure compliance.

For instance, sourcing compliant materials can be particularly challenging and expensive. Manufacturers may find that their usual suppliers do not provide materials that adhere to these new standards, necessitating the search for alternate suppliers or even establishing new supply chains altogether. This shift can delay production times and escalate expenses considerably.

The burden of duplicate regulations

The complexity of having multiple overlapping regulations can also lead to inefficiencies and increased costs. In many cases, regulations are contradictory or duplicative, adding a layer of confusion that burdens manufacturing operations. As companies work to decode these intricate rules, they often find themselves spending time and resources on navigating compliance rather than enhancing their production processes.

The world of electronics manufacturing is significantly influenced by regulations aimed at promoting sustainability and safety. For instance, the RoHS Directive mandates the reduction of hazardous substances in electronic devices, forcing manufacturers to invest in compliant materials. This compliance can increase costs by as much as 15%, impacting profit margins and pricing structures.

Furthermore, the complexity of these regulations can lead to inefficiencies across the supply chain. Many companies struggle with overlapping or poorly designed rules that create administrative burdens. In fact, a recent report indicated that navigating regulatory frameworks can result in increased lead times by approximately 20%, ultimately affecting the speed to market.

In addition, the push for eco-friendly electronics drives the adoption of stricter environmental standards. A surge in consumer awareness has also compelled manufacturers to adapt their practices, showcasing the necessity for compliance not just from a legal standpoint, but also as a means to meet market demand. As the electronics sector continues to evolve, balancing regulatory requirements with operational efficiency will remain a crucial challenge.

The realm of electronic manufacturing is increasingly shaped by an intricate web of regulations that significantly influence its trajectory. On one hand, adhering to strict compliance standards often leads to heightened operational costs, as businesses strive to procure eco-friendly materials and implement necessary processes. However, these regulations are not merely burdensome; they can drive innovation, pushing manufacturers towards more sustainable practices. With the global spotlight on environmental impact, companies are compelled to rethink their supply chains and embrace practices that reduce waste and promote responsible consumption. Thus, while regulations present challenges, they simultaneously offer a pathway to a more sustainable electronics industry, fostering growth that aligns with both consumer expectations and environmental stewardship.

FAQ

What are the primary regulations affecting the electronics manufacturing sector?

R: The electronics manufacturing sector is influenced by various regulations aimed at ensuring safety, environmental protection, and product compliance. Key regulations include the RoHS Directive, which restricts hazardous substances, and REACH, which addresses chemical safety.

How do regulations impact the costs of electronics manufacturing?

R: Adhering to regulations often results in increased costs throughout the supply chain. Companies may incur higher expenses in sourcing compliant materials, implementing necessary adjustments in manufacturing processes, and conducting testing for compliance.

What is the role of environmental regulations in electronics manufacturing?

R: Environmental regulations play a crucial role in minimizing the ecological footprint of electronics manufacturing. These regulations encourage the development of eco-friendly products and promote sustainable practices, thus addressing global environmental concerns.

How do manufacturers ensure compliance with evolving regulations?

R: To maintain compliance, manufacturers must stay informed about changing regulations and continuously adapt their processes. This involves investing in training, updating supply chains, and collaborating with regulatory bodies to ensure that their products meet both national and international standards.

What challenges do electronics manufacturers face due to regulations?

R: Manufacturers encounter several challenges, including the complexity of regulations, which can lead to duplicative and ineffective rules. These challenges create an unnecessary burden, often complicating production processes and potentially impacting overall efficiency and profitability.