|

IN BRIEF

|

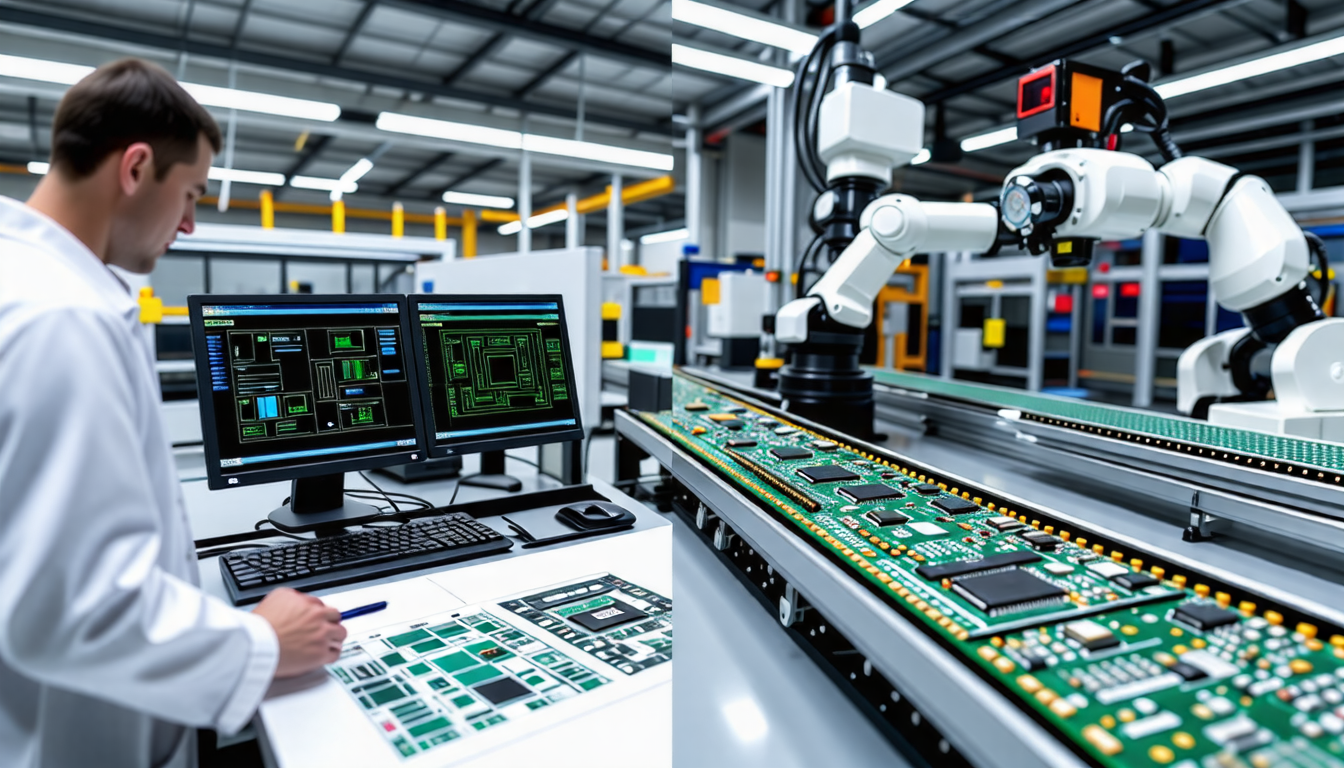

In the dynamic realm of the electronics industry, the supply chain serves as the invisible backbone that supports innovation and ensures efficiency. From the moment a customer places an order to the final delivery, the intricate supply chain process orchestrates every step, weaving together suppliers, manufacturers, and logistics providers. As technology advances, understanding this multifaceted network becomes essential for companies aiming to thrive in a competitive market. Supply chain management not only enhances forecasting and cost efficiency but also fortifies reliability and safety within operations. With challenges such as rising labor costs and fluctuating material prices, navigating the complexities of the electronics supply chain is more crucial than ever, proving that effective collaboration and strategic planning can lead to substantial growth and sustainability.

The electronics industry operates in an intricate ecosystem where components, raw materials, and finished products constantly move between various entities. A clear grasp of the supply chain process is essential for all stakeholders, from manufacturers to retailers, to ensure efficiency, reliability, and sustainability. Understanding this process entails looking into different stages, challenges, and practices that optimize supply chain management.

Supply Chain Transparency

The demand for transparency across supply chains is intensifying, driven by consumers’ desire to understand the sourcing and production processes behind products. Organizations are expected to share detailed information about their supply chains, fostering trust and accountability. Implementing traceability measures can empower companies to provide consumers with the information they seek while minimizing risks associated with non-compliance.

As the electronics industry continues to innovate, the significance of understanding and optimizing the supply chain process will be paramount. By focusing on collaboration, technological advancements, and sustainability, companies can navigate the complexities of the supply chain effectively and create value for their customers.

Raw Material Suppliers

At the beginning of the supply chain, raw material suppliers provide the necessary inputs required to produce electronic components. These materials can include metals, plastics, silicon, and other specialized substances essential in manufacturing semiconductors and circuit boards. Building strong relationships with suppliers is crucial to secure quality materials and manage costs effectively.

Understanding the supply chain process in the electronics industry is crucial as it directly affects efficiency and cost management. As of 2024, the industry continues to experience rising labor costs alongside fluctuations in material expenses. This makes it vital for companies to streamline their operations effectively.

One of the primary challenges facing manufacturers is the increasing complexity of global supply chains. For instance, manufacturers have reported that supply chain disruptions cost them as much as 20% of their operating income over the past year. Such financial strain underscores the necessity of establishing robust inventory management systems and enhancing collaboration with suppliers.

Furthermore, a well-structured supply chain can help in forecasting demand more accurately, allowing companies to respond swiftly to market trends. In addition, it plays a significant role in inventory control, ensuring that production aligns closely with customer needs.

In conclusion, grasping the intricacies of the supply chain process enables electronics manufacturers to not only survive but thrive in this competitive landscape.

In today’s dynamic electronic landscape, understanding the supply chain process is not just beneficial; it’s essential. As the demand for innovative consumer electronics continues to rise, manufacturers must not overlook the intricate web that connects suppliers, manufacturers, and customers. An efficient supply chain ensures timely delivery, cost-effectiveness, and optimal resource utilization, driving the industry towards sustainability and minimizing waste. With challenges such as increasing labor costs and fluctuating materials pricing, the ability to quickly adapt and manage these complexities becomes vital. By prioritizing collaboration and investing in robust management software, companies can navigate the shifting tides of the market, fostering a resilient supply chain that supports both current needs and future growth.

FAQ

What is the supply chain process in the electronics industry?

R: The procurement of raw materials is the first step in the supply chain process, followed by manufacturing, where products are created. After manufacturing, distribution takes place, ensuring that the products reach retailers and customers efficiently.

What are the main challenges faced in electronics supply chain management?

R: Common challenges include inventory management, ensuring supplier collaboration, dealing with rising labor costs, and managing fluctuations in demand forecasts. Additionally, maintaining the security of supply chains and mitigating risks are critical.

How does supply chain management improve efficiency in electronics manufacturing?

R: Effective supply chain management streamlines processes, leading to improved efficiency by minimizing waste and reducing lead times. It facilitates better scheduling and forecasting to ensure timely production and distribution.

Why is supplier collaboration important in the electronics supply chain?

R: Strong collaboration with suppliers enhances communication and trust, leading to better quality control and faster response to changing market demands. This collaboration is essential for addressing challenges quickly and efficiently.

What role does technology play in electronics supply chain management?

R: Technology plays a crucial role by providing innovative tools for inventory management, data analysis, and real-time tracking of shipments. It enhances the overall efficiency, reliability, and security of the supply chain process.