|

IN BRIEF

|

As we venture into a new era of innovation, the electronics manufacturing industry stands at the cusp of transformation. With advancements lighting the path, we witness a surge in smart technologies powered by the Internet of Things and artificial intelligence. These elements, intertwined with the growing demand for sustainable solutions, are redefining the landscape of production and design. From wearable devices to state-of-the-art quantum computing, the industry is evolving rapidly, driven by a quest for efficiency and functionality. Startups are daring to innovate in component design, aimed at pushing boundaries and enhancing our daily interactions with technology. This vibrant atmosphere fosters a spirit of continuous improvement, paving the way for an exciting future in electronics. Join us as we explore these exhilarating trends shaping the industry today!

The electronics manufacturing industry is undergoing a transformative shift. Various trends are emerging, powered by technological advancements and changing consumer demands. As we embrace the future, key themes are rapidly redefining this sector, from the influence of artificial intelligence to the growth of sustainable practices.

The Growing Importance of Cybersecurity

As manufacturers embrace digital solutions, the importance of cybersecurity in electronics manufacturing is amplifying. With increased connectivity and data exchange, the sector faces heightened risks of cyberattacks. Thus, ensuring robust cyber defenses is paramount to protecting intellectual property and sensitive information.

Companies are investing in advanced security measures to safeguard their operations, emphasizing the need for continuous monitoring and updates to their cybersecurity frameworks.

As these trends shape the electronics manufacturing industry, companies must remain adaptable and forward-thinking. The embrace of technologies such as AI, IoT, and automation, coupled with a commitment to sustainability and resilience in supply chains, will be crucial for thriving in this innovative and competitive landscape.

Internet of Things (IoT) in Manufacturing

The role of the Internet of Things (IoT) in electronics manufacturing cannot be overstated. By connecting devices and machinery, manufacturers can gather and analyze data like never before. This connectivity facilitates a comprehensive view of the manufacturing process, allowing companies to monitor performance and make data-driven decisions on the fly.

IoT devices can track inventory levels, monitor equipment performance, and even oversee the production process. They transform traditional manufacturing facilities into smart factories, where every component is in constant communication. As a result, manufacturers find themselves in a position to enhance product quality and operational efficiency.

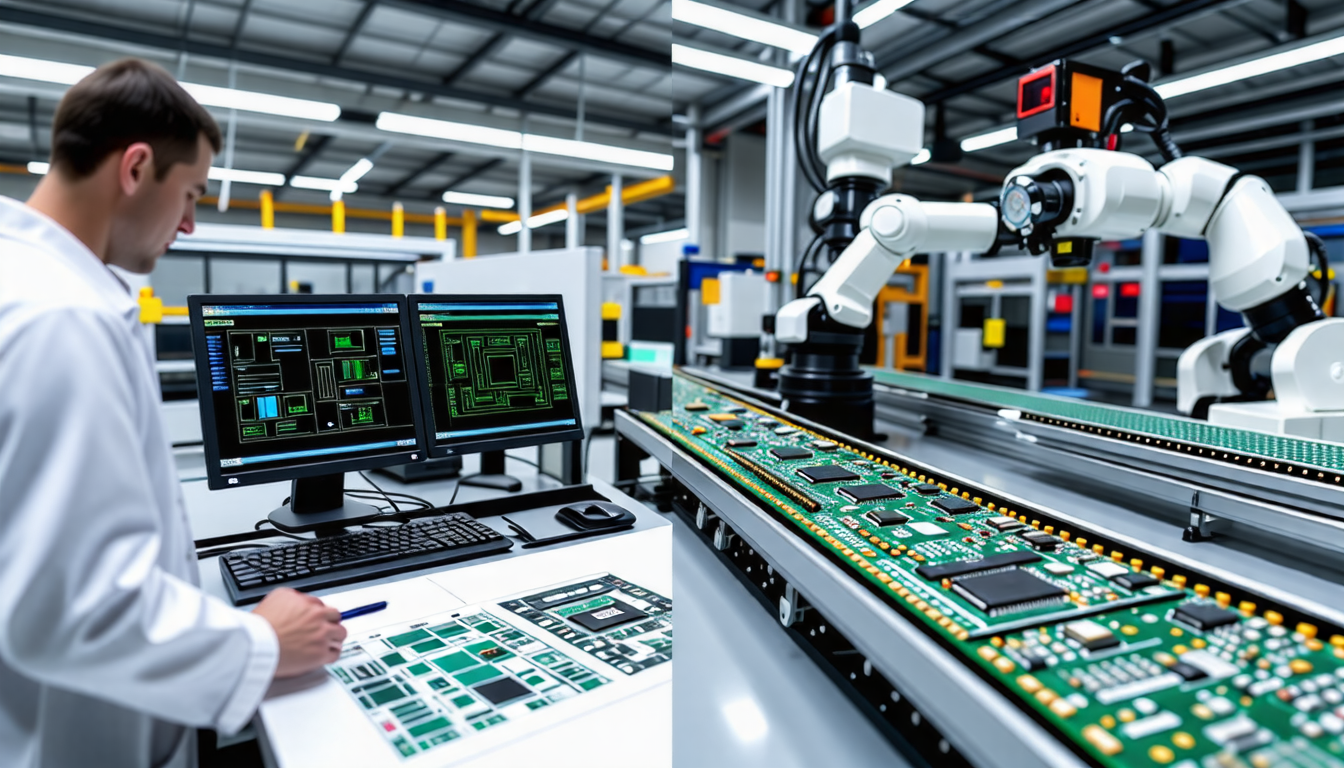

Automation and Robotics

Another critical trend is the increasing reliance on automation and robotics. These technologies are eliminating labor-intensive processes, leading to higher productivity levels. Automated systems can manage repetitive tasks with precision, significantly reducing the chances of human error.

Furthermore, as labor costs continue to rise in many countries, automation offers a viable solution for companies seeking to maintain competitiveness. The use of robotics extends beyond just cost-saving measures; it also opens the door for enhanced safety and efficiency in manufacturing processes.

Collaborative Robots (Cobots)

The emergence of collaborative robots (cobots) further emphasizes the trend toward automation. Unlike traditional industrial robots, cobots are designed to work alongside human operators. They can assist in various tasks, from assembly to quality control, without needing to operate in isolation.

By fostering collaboration between humans and machines, cobots are revolutionizing how manufacturing tasks are executed, making production processes more flexible and adaptable.

The electronics manufacturing industry is undergoing rapid transformation driven by cutting-edge advancements and evolving consumer expectations. As we move towards 2025, several key trends are emerging that are reshaping the landscape. First and foremost, the integration of artificial intelligence (AI) and Internet of Things (IoT) technologies is revolutionizing smart manufacturing. These technologies enhance efficiency, reduce production costs, and improve product quality.

Moreover, there is a noticeable surge in demand for wearable devices and smart gadgets, spurred by consumer interest in connectivity and health monitoring. The global market for wearable technology is projected to reach approximately $62 billion by 2025, indicating significant growth in this sector.

Additionally, sustainability is becoming increasingly crucial. Manufacturers are focusing on green electronics and are better aligning their practices with environmental regulations to meet consumer expectations and comply with standards. For instance, understanding environmental regulations is essential for navigating the compliance landscape.

Finally, as the industry embraces more automation and utilizes big data, implementing effective quality control measures will be vital for maintaining competitive edge in this evolving marketplace.

The electronics manufacturing industry is undergoing a significant transformation, with innovation propelling it into a future defined by cutting-edge technologies and evolving consumer needs. Central to this shift is the rise of artificial intelligence, driving the shift toward smart manufacturing processes that enhance efficiency and productivity. Additionally, the integration of Internet of Things (IoT) technologies is reshaping how devices communicate, resulting in a more interconnected world. The demand for sustainable practices is also on the rise, prompting manufacturers to adopt eco-friendly materials and processes. As we navigate these trends, the industry continues to adapt, fostering a landscape ripe for innovation and growth, aligning technology with the needs and aspirations of society.

FAQ

What are the key trends currently shaping the electronics manufacturing industry?

R: The industry is witnessing significant shifts driven by AI technologies, the rise of IoT devices, and the push for sustainable manufacturing. These trends are geared towards enhancing efficiency and responsiveness in production processes.

How is automation impacting electronics manufacturing?

R: Automation is revolutionizing the manufacturing landscape by offering increased productivity, reduced human error, and enhanced accuracy. This trend leads to smarter factories that can adapt quickly to changing consumer demands.

What role does generative artificial intelligence play in this sector?

R: Generative artificial intelligence is transforming product design and development. It allows engineers to create innovative designs rapidly and efficiently, optimizing both costs and time in the production cycle.

Why is there a growing need for green electronics?

R: The increasing awareness of environmental sustainability is pushing manufacturers to adopt greener practices. This encompasses everything from energy-efficient devices to eco-friendly disposal methods that minimize ecological impact.

What future technologies should we anticipate in electronics manufacturing?

R: In the upcoming years, we can expect advancements in quantum computing, wearable devices, and further integration of augmented reality (AR) and virtual reality (VR) in design and training processes, setting the stage for a transformative wave in manufacturing methods.