|

IN BRIEF

|

In the ever-evolving landscape of technology, miniaturization in electronics stands out as a groundbreaking phenomenon reshaping our world. This fascinating process involves the clever design and manufacture of increasingly smaller yet highly efficient electronic components. As our appetite for compact devices and enhanced mobility grows, the need for smaller physical structures, without compromising functionality, has become more crucial than ever. Think about it: from sleek smartphones that fit snugly in our pockets to intricate circuits that power our modern gadgets, each advancement in miniaturization brings us closer to a future where size and performance seamlessly coexist. This revolution not only paves the way for innovation but also challenges engineers to rethink traditional manufacturing paradigms, ushering in a new era of electronic possibilities.

Miniaturization in electronics is a transformative journey that focuses on reducing the size of components while maintaining or improving their performance. This process has become increasingly relevant due to the growing demand for more compact gadgets that fit seamlessly into our lives. In examining miniaturization, we can explore various aspects, including its historical progression, the techniques employed, and the future implications of these advancements.

Challenges and Considerations

Despite its advantages, miniaturization presents challenges that engineers and designers must address. One major concern is the heat dissipation in compact electronic devices. As components get smaller, managing heat becomes increasingly difficult, risking performance and longevity. Innovations in thermal management technologies will be essential to ensuring reliability in miniaturized systems.

In summary, miniaturization is a remarkable process that continues to revolutionize the landscape of electronics. Through understanding its history, methodologies, and implications, we can anticipate a future filled with even greater opportunities for compact innovation, reshaping how we interact with technology as we delve deeper into this exciting frontier.

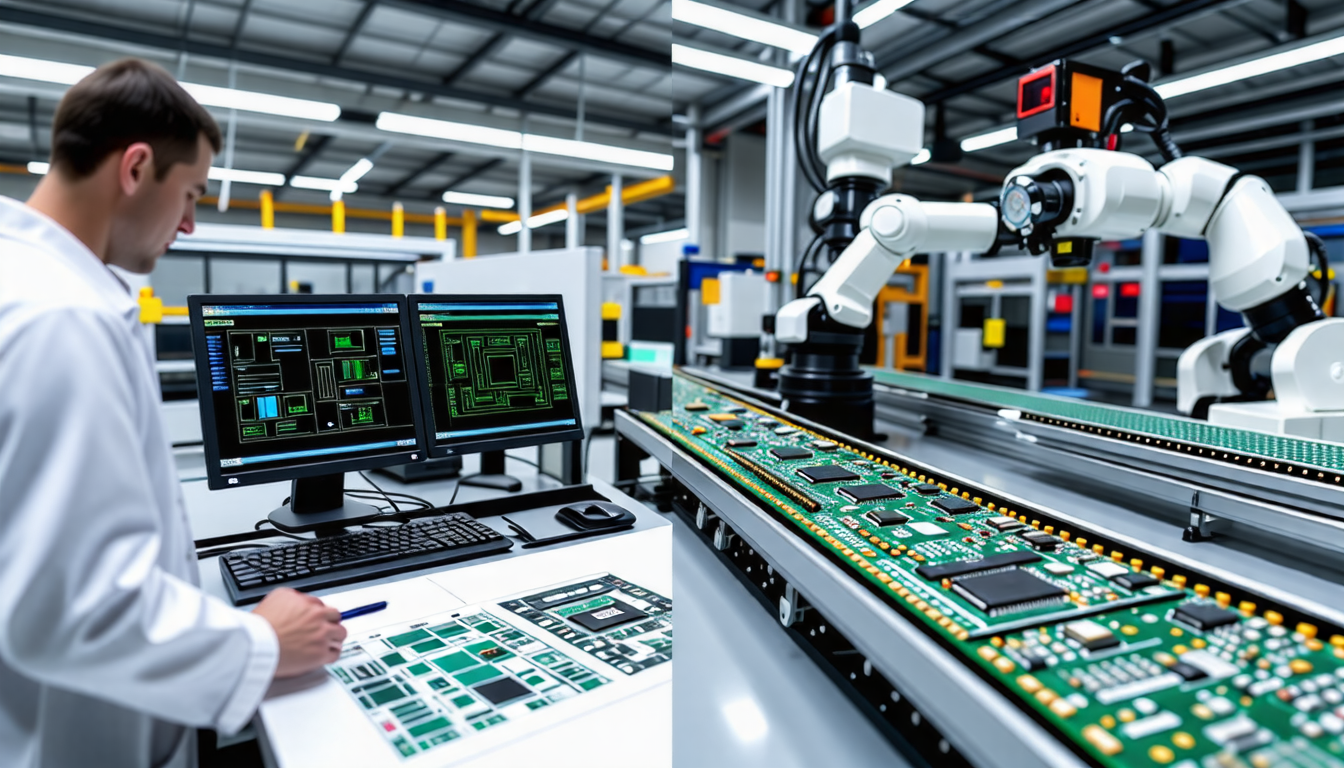

Emergence of Surface Mount Technology (SMT)

In the late 20th century, Surface Mount Technology (SMT) emerged as a significant advancement in the production of compact electronics. SMT allows components to be mounted directly onto the surface of printed circuit boards (PCBs), facilitating much denser layouts. This technology enabled manufacturers to reduce the space required for each component while enhancing performance. The transition to SMT was pivotal as it supported the burgeoning miniaturization trend, leading to smaller size yet highly functional electronic devices.

The process of miniaturization in electronics is a fascinating evolution of technology that focuses on designing smaller, yet more efficient devices. Historically, the trend has gained momentum since the 1970s, when engineers began to realize that reducing the size of electronic components could lead to enhanced performance and accessibility. By the year 2020, the global miniaturization market was valued at approximately $283 billion and is projected to grow significantly, highlighting its significance in modern technology.

One key aspect of miniaturization is the development of advanced assembly techniques that allow for the integration of multiple functionalities into a compact footprint. For instance, the use of flexible printed circuit boards (PCBs) has revolutionized the way electronic devices are constructed. These boards facilitate tighter layouts and enable the use of smaller components, which is essential for the creation of slim gadgets such as smartphones and wearable technology.

Moreover, the shift towards Molecular Electronics exemplifies how the miniaturization process harnesses the benefits at a molecular level to create devices that consume less power while providing the same, if not better, capabilities. As technology continues to advance, the integration of nano-scale components is expected to play a crucial role in meeting the growing demand for smaller and more efficient electronic devices.

The process of miniaturization in electronics represents a transformative journey in the design and manufacturing of electronic components. By embracing innovative techniques and cutting-edge technology, engineers strive to create devices that are not only smaller but also more efficient and functional. This meticulous process involves the integration of advanced materials and precision engineering, allowing for the compact assembly of circuits without compromising performance. As we witness the evolution of microtechnology, the benefits are abundant – from enhancing portability in consumer electronics to paving the way for groundbreaking applications in various industries. The ongoing trend of miniaturization continues to shape the future of electronics, making it an exciting field ripe with possibilities.

FAQ

R: The process of miniaturization in electronics involves designing and manufacturing electronic components that are smaller and more compact. This includes the use of advanced technologies to reduce the size of circuit boards, chips, and other essential parts while maintaining their functionality and performance.

Why is miniaturization important in electronics?

R: Miniaturization is crucial as it allows for the development of smaller, lighter devices that are easier to integrate into various applications. It facilitates advancements in portable technology, enhances energy efficiency, and meets the increasing consumer demand for compact devices.

What are the benefits of miniaturization in electronics?

R: The benefits of miniaturization include increased efficiency in manufacturing, reduced material costs, and the capability to create devices with improved functionality despite their smaller size. It also leads to enhanced performance and the possibility of new innovative products.

What technologies are driving miniaturization?

R: Technologies driving miniaturization include advancements in semiconductor manufacturing, the use of nanotechnology, and innovations in materials such as flexible circuit boards and advanced packaging solutions. These technologies allow for more compact designs without compromising on performance.

How does miniaturization impact the future of electronics?

R: Miniaturization is set to significantly impact the future of electronics by enabling the creation of more sophisticated and multifunctional devices. It paves the way for the Internet of Things (IoT), wearable technology, and the next generation of smart devices, ensuring that technology keeps evolving to meet modern needs.